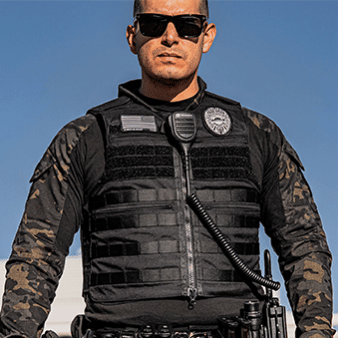

When it comes to tactical gear such as body armor, you have a lot of options. From different protection levels to different brands and materials – there are a lot of factors that need to be decided when you are trying to buy a bulletproof vest, or a plate carrier and other tactical gear, tools, and accessories associated with it.

Today, we are going to talk about ballistic protection tactical gear worn by the military, law enforcement, and civilian customers for protection against rifle rounds. Though a soft armor ballistic vest is great for protection against handgun calibers, it won’t do you much good if you are being shot by a rifle round.

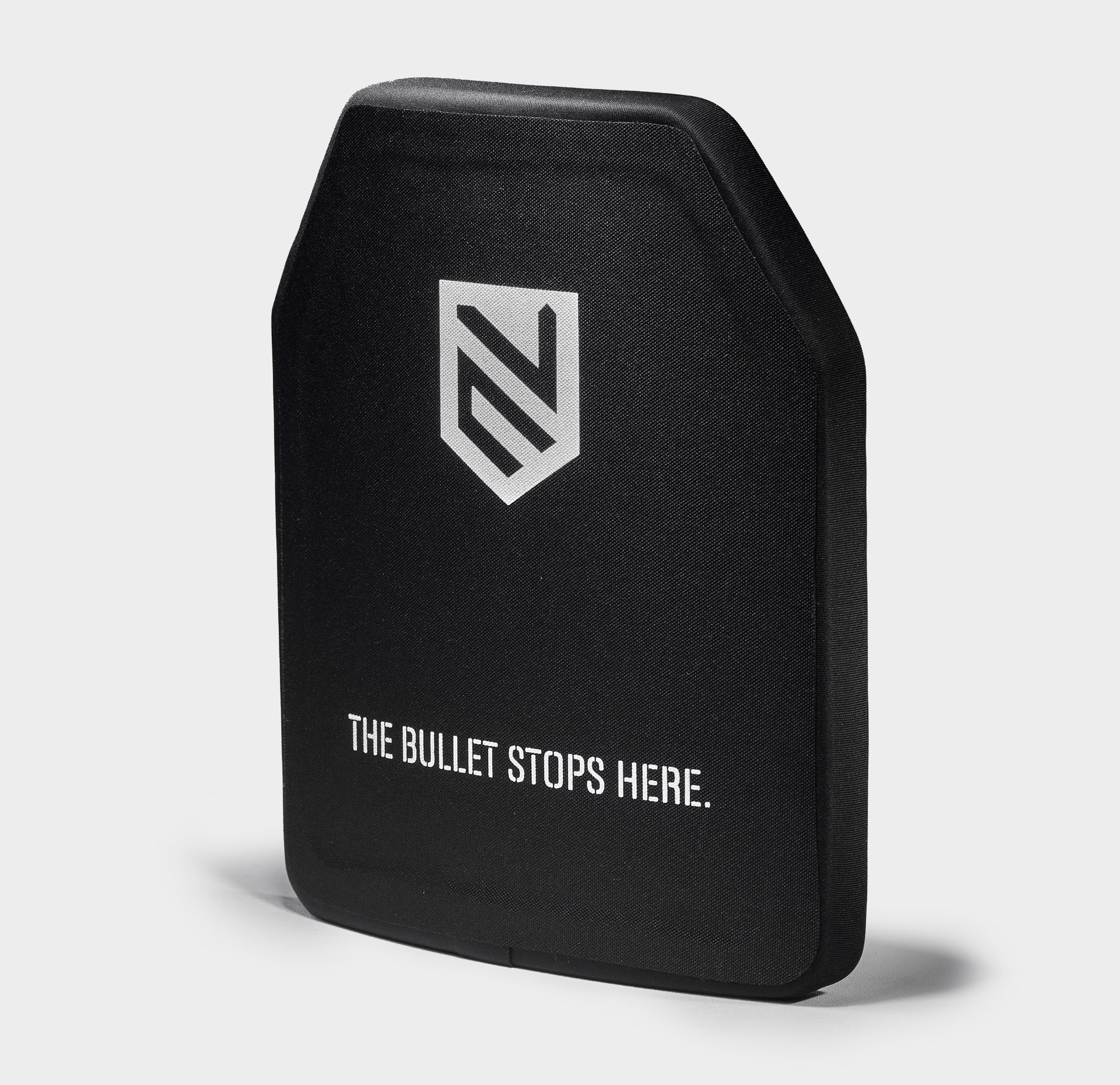

That’s where hard armor plates come in. These plates are worn in plate carriers and can be made from different materials. Though steel is a common material used for making hard body armor plates, is it the safest? Let’s talk about it in more detail.

WHAT MATERIALS ARE ARMOR PLATES MADE FROM?

When manufacturing hard body armor, whether it is for the military, law enforcement, tactical gear freaks or civilian customers, there are many things that need to be considered:

- Ballistic material used

- Weight,

- Structural integrity,

- Shelf life,

- Safety of the wearer

Modern-day body armor manufacturers use many different ballistic materials to make body armor. Below you can find a list of the most popular materials used in the production of tactical gear such as armor plates.

AR 500 STEEL

Abrasion-resistant (AR) steel plates are a high carbon alloy designed to be formable and weather resistant. The addition of alloys, makes them harder when heat treated as well making it excellent for projects that need material failure from wear or abrasion rather than extreme temperatures like welding torch flames where there is more chance at volatilization which would cause destruction over time even if covered with paint etc., but not something you want happening during everyday use either!

Many body armor manufacturers in the world make AR500 steel armor plates, and though they have the longest shelf life and potential for reusability, they also aren’t the safest according to many people. Moreover, they are also very heavy, which can affect maneuverability.

CERAMIC ARMOR PLATE

Ceramics like Aluminum Oxide, Silicon Carbide, or Boron Carbide are other common materials used to make body armor. Ceramic body armor usually consists of UHMW Polyethylene backing and ceramic adhered to its surface. Ceramic is lightweight and makes incoming rounds break up which makes it easier for PE backing to absorb their impact.

They are lighter than steel as well, however, once they are shot, even with a small caliber, their protective capabilities may start to decrease.

UHMW POLYETHYLENE

In recent years, manufacturers have also started making body armor solely from Ultra High Molecular Weight Polyethylene. UHMW PE body armor is lightweight and durable, with a longer shelf life as well. It is significantly safer than steel body armor. However, UHMW PE is only strong enough to make level III armor plates, for higher protection Ceramic and steel hybrid plates are a better option.

What is important to mention, PE plates have neutral or positive buoyancy which means they will float when dropped in the water.

WHY STEEL ARMOR PLATES ARE NOT SAFE

One of the biggest reasons why most military personnel and civilians shy away from using steel armor is Spalling. Now, you are probably wondering what is spalling?

Well, it is quite simple, when a fast-moving bullet hits a solid steel plate, what do you think is going to happen? The bullet will obviously break into fragments. However, those fragments can’t be controlled by steel plates, and instead, they are deflected to the sides and sometimes even upwards towards the neck of the person wearing armor. These fragments and deflected bullets can carry enough energy to mortally injure someone.

This can be extremely dangerous, as it can seriously injure anyone who is wearing a steel armor plate and the people around them as well. Furthermore, the deflecting fragments can damage your plate carriers, and other tactical gear, tools, and weapon accessories you are carrying on your plate carriers. The fragment can damage your magazines, communication gear, med packs, and any other tactical gear tools you may have. To conclude this part, it should be noted that steel armor has been phased out by most military forces around the world mainly because spalling makes it less safe and more difficult to use than other materials like for example Polyethylene.

Typically, the internal safety lining of a bulletproof helmet is made from foams, rubbers, or plastics, and you can also find some hybrid options. Foam padding offers the most comfort. A tactical helmet can use foams of varying densities, made from open cell and closed cell polyester, polyurethane, polyethylene.

Almost every helmet comes with some sort of padding to ensure a comfortable fit, and to mitigate the impact of any projectiles. However, aftermarket comfort pads are also available, which can significantly improve the wearability of a helmet.

After the padding, the interior lining of a helmet is also important. Most helmets have a mesh lining on the inside, to keep your head cool, and avoid excessive sweating when working for a long time.

IS THERE A SOLUTION TO SPALLING?

Well, yes there is one solution that most manufacturers use, but even that isn’t ideal. They actually coat the front of the steel armor plate with a heavy rubberized layer, which catches all the fragments in it when it is shot.

However, the solution only works for the first few shots, if you are in a situation where you could be shot more than once, which is quite possible for the military and special law enforcement units, the rubber coating comes off, and Spalling becomes a problem. Now you know why many people prefer other types of material over steel. You should understand now why several militaries enforce their personnel to not use steel armor plates in combat situations for personal protection (odds are if there’s a war happening somewhere in the world right now, any US soldier stuck fighting isn’t wearing steel armor).

The future will likely bring us lighter and better materials than this for body armor, but right now it’s complicated by the fact that you want to stop bullets, yet also allow penetration by knives and other stabbing weapons (this is why vests designed for cops are mostly ceramic on the front half while Kevlar covers their back).

WHY IS STEEL ARMOR BAD?

Well, apart from the major spalling issue, here are some other reasons why steel armor is not the best option:

STEEL DO NOT ABSORB IMPACT ENERGY

When you take a hit with steel armor in your plate carriers, the bullet may not penetrate, but you still won’t be in much of a position to continue fighting. Steel plates are notoriously bad at absorbing the power of the bullet when it makes contact on the plate, and even when the round does not penetrate, you will feel like you have been punched really hard. Many times, this leads to broken ribs, and sometimes even a collapsed lung.

STEAL ARMOR IS HEAVY

The weight of armor plates makes a lot of difference, especially for military and law enforcement personnel who have to wear their plate carriers all day. Two heavy steel panels for the front and back, combined with all the tactical gear, tools, packs, bags, and gun accessories a plate carrier can get a bit too heavy to handle, and it decreases movement and maneuverability as well.

A 10” x 12” steel plate can weigh somewhere between 8-10 pounds, whereas ceramic armor of the same size weigh half of that, and PE armor are even lighter.

STEEL ARMOR IS UNCOMFORTABLE

Another reason why you should avoid steel armor is that it is uncomfortable. Most steel ballistic panels are straight, though a slightly curved plate is more comfortable, if a steel plate is curved, the chances of ricochet are increased.

It can make it difficult to move around, carry your tactical gear, and even perform simple tactical maneuvers.

WHAT KIND OF ARMOR PLATES ARE SAFE?

So, now that we have established that steel armor is not the safest option, let’s talk about the kinds of armor you should better use. If you want basic protection against pistol rounds, you can get a ballistic vest with soft armor inserts made out of Aramid Kevlar fabric. They are the most comfortable as they adapt to your body contour. Exactly like a plate carrier, bulletproof vest can carry any kind of tactical gear or tools as needed.

On the other hand, if you are looking for protection against bigger calibers, you should opt for ceramic or PE armor. For level III protection (up to an FMJ .308 Winchester) PE armor seems to be the best, it is durable, easy to store and maintain, and most importantly – polyethylene armor plates are lightweight. Moreover, it is safe since the PE fabric absorbs the fragments of the bullet rather than deflecting them.

Now, if you are looking for level IV armor protection (up to. 30-06 Armor Piercing rounds), things are a bit different. Most of the time, these plates are made with multiple layers, in some cases, a ceramic strike face, and a polyethylene or aramid backing. These plates are safe because the ceramic catches the fragments, and spalling is not an issue. While they can be heavier than most PE plates – we have a solution for you: Level 4 Body Armor Plate that weights only 6.0 lbs and stops multiple armor piercing rounds. Therefore, ceramic and polyethylene composite armor panels are ideal for level IV protection. The US military also uses PE and Ceramic armor for both level III and level IV protection.

SUMMARY

So, when it comes to tactical gear, body armor is extremely important, and you want the kind of armor that saves your life and makes unsafe situations safer. However, in the case of steel armor, the effect could be the opposite.

Having to wear heavy and thick steel plates it’s not the best choice when it comes to choosing your armor plates because you’re compromising mobility, dexterity, and aim. Steel armor panels are not the safest, they can deflect bullets toward the person wearing the armor, and are really bad at absorbing the impact force of bullets. They are also heavy and uncomfortable.

We hope that this post helped you learn more about what kinds of ballistic armor panels are the best choice. Thanks for reading!