- Table of Contents

- Quick Summary

- What are the Different Material Types in Body Armor?

- Why Material Selection is Crucial for Protection?

- How Do Various Materials Function for Ballistic Resistance?

- Key Properties and Applications of Armor Materials

- Current Trends and Innovations in Body Armor Materials

- Protect Yourself with Materials That Make a Difference

- Frequently Asked Questions

- Recommended

Body armor has evolved from heavy slabs of metal to cutting-edge science woven into every layer. Today’s advanced materials like Kevlar can be up to five times stronger than steel by weight. Most people expect metal plates to do the heavy lifting against ballistic threats. But the real secret is in the chemistry. Modern fibers and ceramic blends not only stop bullets but keep protection light enough for all-day wear, challenging everything you thought you knew about how body armor really works.

Table of Contents

- What Are The Different Material Types In Body Armor?

- Why Material Selection Is Crucial For Protection?

- How Do Various Materials Function For Ballistic Resistance?

- Key Properties And Applications Of Armor Materials

- Current Trends And Innovations In Body Armor Materials

Quick Summary

| Takeaway | Explanation |

|---|---|

| Synthetic fibers provide lightweight ballistic protection. | Materials like Kevlar and Dyneema are key for effective, lightweight body armor with high strength-to-weight ratios. |

| Composite armor combines multiple materials for better defense. | Using ceramic plates with synthetic fibers enhances protection while reducing weight and improving mobility for the wearer. |

| Material selection impacts comfort and survivability. | Choosing the right materials influences not only ballistic resistance but also ongoing comfort and reliability for users in the field. |

| Innovations include nanotechnology for enhanced performance. | Emerging technologies, such as nanoscale structures, are transforming body armor, offering greater toughness and adaptability compared to traditional materials. |

| Layering strategies are essential for effective protection. | Mixing materials provides both energy absorption and impact resistance, creating a robust system against various ballistic threats. |

What are the Different Material Types in Body Armor?

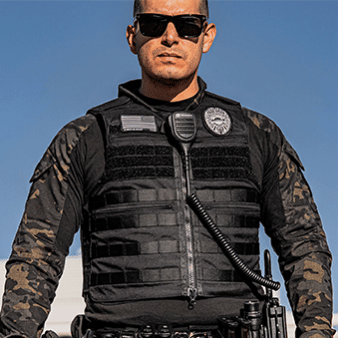

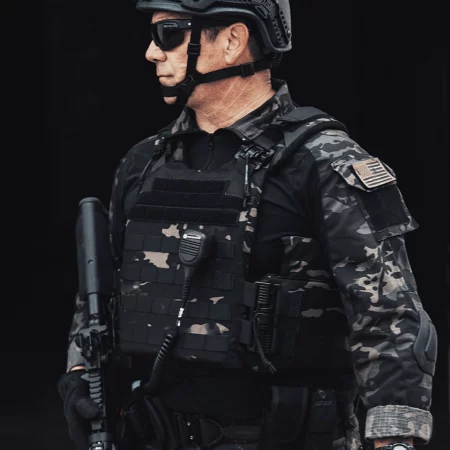

Body armor materials represent a critical technological intersection of science, engineering, and personal protection. The selection of appropriate materials directly determines the effectiveness, weight, and overall performance of protective gear used by law enforcement, military personnel, and security professionals. Learn more about protective gear selection.

Synthetic Fiber Materials

Synthetic fibers form the foundational material for many modern body armor designs. Aramid fibers like Kevlar and Dyneema represent revolutionary advancements in ballistic protection. These high-performance polymers offer exceptional strength-to-weight ratios, allowing manufacturers to create lightweight yet incredibly robust protective gear.

According to research from the National Institute of Justice, synthetic fibers can effectively dissipate and distribute kinetic energy from projectiles, significantly reducing potential bodily harm. The molecular structure of these materials allows them to rapidly absorb and disperse impact forces, creating a protective barrier that can stop bullets and reduce traumatic injury.

Composite and Ceramic Materials

Advanced body armor often incorporates composite materials that combine multiple protective elements. Ceramic plates, typically made from aluminum oxide or boron carbide, provide exceptional hard armor capabilities. These materials are designed to fracture and ablate upon impact, effectively neutralizing projectile energy.

The primary advantages of ceramic composites include:

- Superior protection against high-velocity rifle rounds

- Significantly reduced weight compared to traditional metal armor

- Enhanced ability to stop armor-piercing ammunition

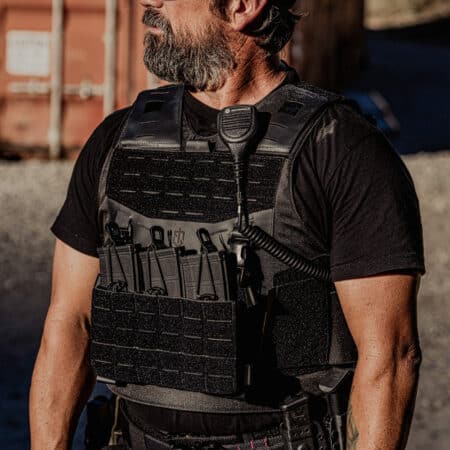

By strategically layering ceramic plates with synthetic fiber backings, manufacturers can create body armor solutions that offer comprehensive protection across various threat scenarios. This multi-material approach ensures that the armor can withstand different types of ballistic threats while maintaining acceptable weight and mobility for the wearer.

To help clarify the unique properties and applications of key body armor materials, the table below compares their main features and how they function under ballistic threats.

| Material Type | Key Properties | Primary Protection Level | Typical Applications |

|---|---|---|---|

| Kevlar (Aramid) | High tensile strength, lightweight, flexible | Handguns, fragmentation | Soft armor for law enforcement |

| Dyneema (UHMWPE) | Extremely light, high strength-to-weight ratio | Handguns, limited rifle rounds | Concealable vests, soft inserts |

| Ceramic Composites | Hard, brittle, shatters to absorb energy | High-velocity rifles, AP rounds | Hard plates for military and police |

| Aluminum Oxide | High hardness, moderate weight | Rifle and armor-piercing rounds | SAPI/ESAPI plates, military vests |

| Boron Carbide | Very hard, lightweight, brittle | Advanced rifle and AP threats | Elite military plates, special forces |

Why Material Selection is Crucial for Protection?

Material selection in body armor represents a critical decision that directly impacts survivability and operational effectiveness. The strategic choice of protective materials determines not just the immediate ballistic performance, but also long-term reliability and user comfort. Explore our comprehensive guide on ballistic protection levels.

Performance and Threat Mitigation

The primary objective of body armor materials is to effectively mitigate potential threats while maintaining optimal performance characteristics. Different materials offer unique protective capabilities against various ballistic challenges. According to research from the National Institute of Justice, material selection must consider multiple critical factors beyond simple impact resistance.

Key performance considerations include:

- Energy absorption and distribution

- Resistance to multiple impact scenarios

- Durability under extreme environmental conditions

- Weight and mobility implications

Technological Limitations and Trade-offs

Each body armor material presents distinct technological limitations and performance trade-offs. Synthetic fibers like Kevlar provide exceptional lightweight protection, while ceramic composites offer superior penetration resistance. However, these materials also have inherent constraints that require careful engineering and strategic design.

The ultimate goal in material selection is creating a balanced protective solution that addresses specific threat environments while maintaining wearer mobility and comfort. This requires a nuanced understanding of material science, ballistic engineering, and operational requirements.

The following table organizes the key performance considerations discussed in the section, outlining their impact on the overall effectiveness and usability of body armor materials.

| Performance Consideration | Description | Relevance to Body Armor |

|---|---|---|

| Energy Absorption | Ability to absorb projectile energy on impact | Essential for stopping bullets |

| Impact Distribution | Spreading force over a wider area | Reduces risk of blunt force trauma |

| Multi-hit Resistance | Endurance against multiple projectile strikes | Determines durability and reliability |

| Environmental Durability | Resistance to temperature, moisture, and wear | Affects long-term performance |

| Weight and Mobility | Overall weight and flexibility of armor | Influences comfort and operational use |

| Professional-grade body armor demands a comprehensive approach that considers not just immediate protection, but long-term reliability and adaptability across diverse threat scenarios. |

How Do Various Materials Function for Ballistic Resistance?

Ballistic resistance is a complex interplay of material science, physics, and engineering principles that determine how protective gear stops and dissipates potentially lethal projectile energy. Check out our detailed armor insert options to understand practical implementations of these scientific principles.

Molecular Structure and Energy Absorption

The fundamental mechanism of ballistic resistance revolves around how different materials respond to high-velocity impact. According to research from the National Institutes of Health, materials like aramid fibers and ultra-high molecular weight polyethylene possess unique molecular structures that enable extraordinary energy absorption capabilities.

Key energy absorption mechanisms include:

- Molecular chain stretching and realignment

- Localized deformation and energy dispersion

- Microscopic fiber interlocking and shear resistance

- Rapid kinetic energy transformation

Layered Protection Strategies

Advanced body armor leverages multiple material layers to create comprehensive protection systems. Synthetic fibers like Kevlar provide flexible energy absorption, while ceramic plates offer hard impact resistance. By strategically combining these materials, manufacturers can develop armor that effectively neutralizes different types of ballistic threats.

The interaction between material layers creates a complex protective mechanism where each component plays a critical role. Soft armor absorbs and distributes initial impact energy, while rigid ceramic plates prevent penetration and further dissipate remaining kinetic forces. This multi-material approach ensures a robust defense against diverse projectile threats, from handgun rounds to high-velocity rifle ammunition.

Key Properties and Applications of Armor Materials

Body armor materials represent a sophisticated intersection of engineering, material science, and protective technology designed to safeguard human life under extreme conditions. Explore emerging technologies in lightweight ballistics that are revolutionizing personal protection strategies.

Mechanical Performance Characteristics

The effectiveness of armor materials is determined by a complex array of mechanical properties that define their protective capabilities. According to research from the National Institute of Justice, critical performance metrics include tensile strength, energy absorption, deformation resistance, and impact resilience.

Key mechanical performance indicators include:

- Tensile strength and molecular bond integrity

- Energy absorption and kinetic force dissipation

- Resistance to permanent deformation

- Ability to maintain structural integrity under repeated impacts

Contextual Applications and Specialized Design

Different operational environments demand specialized armor material configurations. Law enforcement, military, and security professionals require materials that not only provide ballistic protection but also accommodate mobility, comfort, and specific threat scenarios. Aramid fibers excel in soft armor applications, providing flexible protection against handgun rounds, while ceramic composites offer superior resistance against high-velocity rifle ammunition.

The strategic selection of armor materials involves a nuanced understanding of threat levels, operational requirements, and the physiological limitations of the wearer. Professional-grade body armor must balance protection, weight, and user comfort to ensure optimal performance in dynamic and unpredictable environments.

Current Trends and Innovations in Body Armor Materials

The landscape of body armor technology is rapidly evolving, driven by breakthrough research and cutting-edge material science. Explore innovative protective solutions for specialized professionals that challenge traditional protective gear limitations.

Nanotechnology and Advanced Composite Materials

Cutting-edge research is transforming body armor through revolutionary nanotechnology applications. According to research from the U.S. Army’s Institute for Soldier Nanotechnologies, emerging nanoscale truss structures are demonstrating unprecedented toughness that surpasses traditional materials like Kevlar and steel.

Key emerging technological innovations include:

- Nanoscale engineered material structures

- Adaptive molecular composite designs

- Self-healing polymeric materials

- Programmable material responses to external threats

Smart and Responsive Material Technologies

The next generation of body armor is moving beyond passive protection toward intelligent, responsive material systems. Researchers are developing advanced composites like liquid armor technologies that dynamically change their molecular structure upon high-velocity impact. These materials can transition from flexible to rigid instantaneously, providing unprecedented protection while maintaining wearer mobility.

The future of body armor lies in creating multifunctional protective systems that adapt to specific threat environments. By integrating advanced material sciences with sophisticated engineering, manufacturers are developing armor solutions that offer superior protection, reduced weight, and enhanced user comfort across diverse operational scenarios.

Protect Yourself with Materials That Make a Difference

Choosing the right body armor is not just about ticking a box. You have just learned how the material inside your armor determines real-life safety and comfort. Whether facing the impact of high-velocity rounds or seeking the lightest, most reliable protection, your decision can mean everything in the moments that count. The need for trusted materials is urgent. Many professionals and security-conscious civilians struggle to find gear that balances weight, flexibility, and serious defense. But with the right expertise, you do not have to compromise.

Why settle for less when your next mission or daily routine demands more? Let AcelinkArmor.com deliver peace of mind with body armor constructed from proven materials like Kevlar, Dyneema, and advanced ceramics. Explore soft armor inserts built from high-performance fibers for everyday use or review emerging lightweight ballistic innovations designed to change your protection strategy. Visit our site now to discover solutions that meet real professional standards. Your safety starts here.

Frequently Asked Questions

What types of materials are used in body armor?

Body armor commonly utilizes synthetic fibers such as Kevlar and Dyneema, as well as composite and ceramic materials. These materials are selected for their strength-to-weight ratios and ability to absorb and distribute kinetic energy from projectiles.

How do synthetic fibers compare to ceramic materials in body armor?

Synthetic fibers like Kevlar offer lightweight protection and flexibility, making them suitable for soft armor applications. In contrast, ceramic materials provide superior protection against high-velocity rifle rounds but can be heavier and less flexible.

Why is material selection important in body armor performance?

Material selection is crucial as it impacts the armor’s ballistic performance, weight, durability, and user comfort. Different materials provide varying levels of protection against specific threats, so careful consideration is necessary for optimal safety and effectiveness.

What is the role of layered protection in body armor?

Layered protection combines multiple materials to create comprehensive defense systems. Soft armor absorbs initial impact energy, while hard armor, such as ceramic plates, prevents penetration and dissipates remaining forces, enhancing overall ballistic resistance.

Recommended

- The Best Types Of Body Armor For Home Defense.

- Types of Ballistic Helmets & How to Choose One

- Measurement, Fit, and Coverage of Body Armor

- How Elections Impact Body Armor Availability