- Table of Contents

- Key Takeaways

- Defining Ceramic Armor and UHMW PE Plates

- Protection Levels And Ballistic Performance

- Weight, Comfort, And Ergonomics Compared

- Durability, Lifespan, And Maintenance Needs

- Use Cases For Law Enforcement And Civilians

- Cost, Availability, And Key Purchasing Factors

- Choose the Right Armor Plate for Your Mission

- Frequently Asked Questions

- Recommended

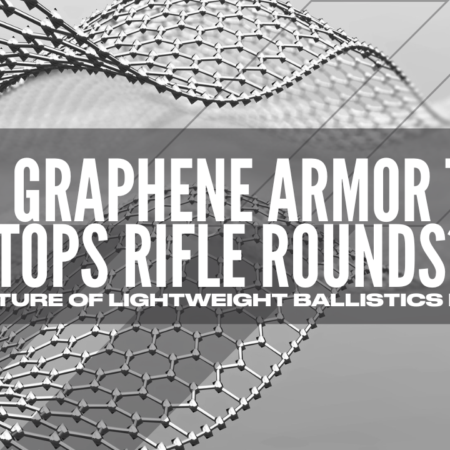

Did you know that modern body armor plates can stop high-velocity rifle rounds while weighing less than four pounds? For law enforcement, military, and security personnel, the right choice between ceramic body armor and UHMW PE armor plates could mean the difference between comfort and comprehensive protection. Understanding how these advanced materials compare in real-world durability, weight, and stopping power helps professionals and civilians stay prepared for whatever threats they might face.

Table of Contents

- Defining Ceramic And UHMW PE Armor Plates

- Protection Levels And Ballistic Performance

- Weight, Comfort, And Ergonomics Compared

- Durability, Lifespan, And Maintenance Needs

- Use Cases For Law Enforcement And Civilians

- Cost, Availability, And Key Purchasing Factors

Key Takeaways

| Protection Type | Key Details |

|---|---|

| Material Composition | Ceramic body armor plates are made from hard materials like aluminum oxide, while UHMW PE plates utilize lightweight polymer fibers for mobility. |

| Ballistic Performance | Ceramic plates typically meet NIJ Levels III and IV, offering superior initial protection, while UHMW PE plates maintain performance across multiple hits at NIJ Level III. |

| Weight and Ergonomics | UHMW PE plates are lighter and more flexible, enhancing user mobility, whereas ceramic plates provide a rigid form for high-threat scenarios. |

| Cost and Maintenance | Ceramic plates range from $200-$600 with higher ongoing replacement costs, while UHMW PE plates are more budget-friendly at $100-$300, requiring less frequent maintenance. |

Defining Ceramic Armor and UHMW PE Plates

Body armor plates represent critical protection technology designed to shield tactical professionals from ballistic threats. Ceramic armor plates and UHMW PE (Ultra-High Molecular Weight Polyethylene) plates offer distinct protective characteristics that make them invaluable for law enforcement, military, and security personnel.

According to research from specialized armor manufacturing sources, ceramic armor plates are engineered from hard ceramic materials like aluminum oxide or silicon carbide. These plates function through a unique mechanism where the ceramic layer fractures upon impact, strategically dissipating and absorbing projectile energy. The ceramic’s inherent hardness allows it to shatter incoming rounds, preventing penetration through a complex energy transfer process. This design creates a robust first line of defense against high-velocity projectiles.

UHMW PE plates represent a revolutionary alternative, constructed from high-density polymer fibers with exceptional strength-to-weight characteristics. Unlike ceramic plates, these lightweight armor solutions utilize long molecular polymer chains to provide remarkable protection. Understanding UHMW PE vs. Aramid for Bulletproof Vest highlights their unique advantage: extreme durability combined with minimal weight burden. These plates excel in scenarios demanding mobility and extended wear, making them particularly attractive for dynamic operational environments.

Key differences between ceramic and UHMW PE plates include weight, durability, and impact resistance. Ceramic plates offer superior initial strike protection but can become compromised after multiple hits. UHMW PE plates provide consistent performance across multiple impacts, maintaining structural integrity under repeated stress. For tactical professionals selecting armor, understanding these nuanced material properties becomes crucial in matching protection needs with operational requirements.

Protection Levels And Ballistic Performance

Understanding the ballistic performance of armor plates is crucial for tactical professionals selecting the right protection. Different materials offer varying levels of defense against projectile threats, with ceramic and UHMW PE plates presenting distinct protective capabilities across NIJ (National Institute of Justice) rating standards.

According to research from specialized body armor sources, ceramic plates typically achieve NIJ Level III and Level IV ratings. NIJ Rated Level IV Armor Plates demonstrate exceptional capability to stop common rifle rounds and even armor-piercing ammunition. These plates excel in initial impact protection, using their hard ceramic composition to fracture and dissipate incoming projectile energy. However, their primary limitation is reduced multi-hit capability – a single significant impact can compromise the plate’s structural integrity.

UHMWPE plates, by contrast, offer robust multi-hit protection across NIJ Level III standards. Unlike ceramic counterparts, these polymer-based plates maintain structural consistency after multiple impacts. They provide reliable defense against non-armor-piercing rifle rounds while offering superior durability. The polymer’s molecular structure allows consistent energy absorption, making these plates particularly valuable in high-stress operational environments where repeated potential threats exist.

Key performance considerations include not just protection level, but also weight, mobility, and sustained defensive capacity.

Ceramic plates provide superior initial strike protection but become vulnerable after penetration. UHMW PE plates trade absolute initial hardness for consistent, reliable multi-hit performance. For tactical professionals, selecting between these plate types requires carefully evaluating specific operational requirements, potential threat environments, and individual mission parameters.

Here’s a comparison of key protection and performance factors:

| Factor | Ceramic Plates | UHMW PE Plates |

|---|---|---|

| NIJ Protection Level | Level III & IV | Level III |

| Weight | 5-7 lbs | 3-4 lbs |

| Multi-Hit Capability | Limited | Strong |

| Durability | Fragile after impact | Maintains integrity |

| Comfort & Ergonomics | Less flexible, heavier | Lightweight, flexible |

| Maintenance | Inspect/replace after hit | Less frequent replacement |

| Cost (per plate) | $200-$600 | $200-$1000 |

Weight, Comfort, And Ergonomics Compared

Body armor performance extends beyond pure ballistic protection, with weight and ergonomics playing critical roles in operational effectiveness for tactical professionals. The choice between ceramic and UHMW PE plates involves carefully balancing protection capabilities with user mobility and long-term comfort.

According to research from specialized body armor manufacturers, UHMW PE plates represent a significant breakthrough in lightweight protection technologies. These plates typically weigh between 3-4 lbs, offering substantial weight reduction compared to traditional ceramic alternatives. Level 3+ Ceramic Plate 10×12″ demonstrates the importance of weight considerations, highlighting how lighter plates can dramatically improve an operator’s mobility and reduce fatigue during extended missions.

Ceramic plates, weighing approximately 5-7 lbs, present a different ergonomic profile. While inherently heavier, they provide superior initial impact protection that can be crucial in high-threat environments. The additional weight translates to increased protection density, which means tactical professionals must balance the trade-off between comprehensive protection and physical mobility. The plate’s contour, edge design, and weight distribution become paramount in determining overall user comfort and movement efficiency.

Ergonomic considerations extend beyond raw weight metrics. UHMW PE plates excel in flexibility and conformity to body movements, reducing restriction during dynamic operational scenarios. Ceramic plates, while less flexible, offer a rigid protection profile that maintains consistent defensive capabilities. For professionals selecting armor, the decision ultimately depends on specific mission parameters – whether prioritizing absolute protection or maintaining maximum mobility and reduced physical strain.

Durability, Lifespan, And Maintenance Needs

The longevity and maintenance requirements of body armor plates are critical considerations for tactical professionals who depend on consistent, reliable protection in high-stakes environments. Durability goes far beyond initial performance, encompassing the plate’s ability to withstand repeated stress and environmental challenges.

Research from specialized body armor manufacturers reveals significant differences in durability between ceramic and UHMW PE plates. Ceramic plates are inherently more fragile, with a critical vulnerability of potentially cracking or shattering after a single significant impact. NIJ Rated Level IV Armor Plates highlight the importance of understanding these material limitations. These plates require meticulous handling and immediate replacement after any substantial strike, which can become both operationally disruptive and financially costly for tactical units.

UHMW PE plates present a dramatically different durability profile. These polymer-based plates demonstrate remarkable resilience, capable of maintaining structural integrity after multiple ballistic impacts. Their molecular composition allows for consistent performance under repeated stress, making them particularly valuable in dynamic operational scenarios. However, users must still exercise caution, protecting these plates from prolonged UV exposure and extreme temperature conditions that could compromise their protective capabilities.

Maintenance strategies differ substantially between these plate types. Ceramic plates demand careful inspection after any potential impact, with strict protocols for immediate replacement. UHMW PE plates offer more forgiving maintenance requirements, allowing for continued use after multiple strikes. For tactical professionals, the choice ultimately depends on balancing initial protection levels, long-term durability, and the specific environmental and operational challenges they anticipate encountering.

Use Cases For Law Enforcement And Civilians

Body armor plate selection is not a one-size-fits-all proposition, with tactical requirements and operational environments driving critical material choices for different professional and personal protection scenarios. Understanding the nuanced applications of ceramic and UHMW PE plates helps professionals and security-conscious civilians make informed protection decisions.

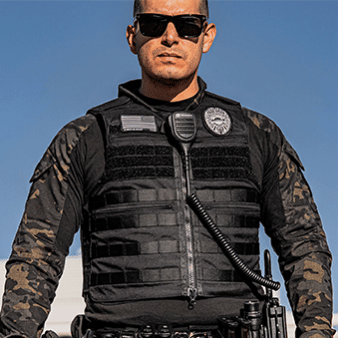

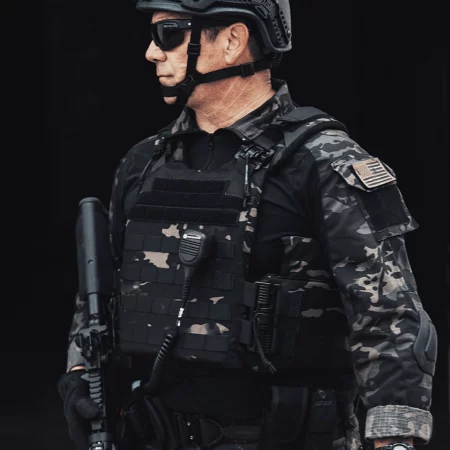

For law enforcement professionals, ceramic plates offer exceptional performance in high-threat urban environments. Understanding UHMW PE vs. Aramid for Bulletproof Vest highlights how different materials serve specialized operational needs. Tactical units responding to potential active shooter scenarios or high-risk warrant service require the superior initial impact protection that ceramic plates provide, especially against armor-piercing ammunition. SWAT teams and specialized response units frequently prioritize these plates for maximum defensive capabilities in unpredictable confrontations.

Civilian and patrol-level applications typically favor UHMW PE plates, which offer an optimal balance between protection and mobility. These lighter plates are ideal for routine law enforcement duties, where extended wear and reduced physical fatigue become critical considerations. Security professionals, private investigators, and civilian protective service operators benefit from the plates’ multi-hit capability and reduced weight, allowing for extended operational readiness without compromising fundamental defensive performance.

Beyond professional use, civilian self-defense applications require careful evaluation of personal risk profiles. Home defense scenarios might prioritize ceramic plates for their superior initial strike protection, while everyday carry and personal protection lean towards the lightweight, versatile characteristics of UHMW PE plates. The ultimate selection depends on individual threat assessments, physical capabilities, and specific personal security requirements.

Cost, Availability, And Key Purchasing Factors

Navigating the body armor market requires a strategic approach to balancing protection, budget, and operational requirements. The financial investment in armor plates extends far beyond initial purchase price, encompassing long-term performance, durability, and potential replacement costs.

Research from specialized body armor manufacturers reveals significant pricing variations between ceramic and UHMW PE plates. Ceramic plates typically range from $200 to $600 per plate, reflecting their complex manufacturing processes and specialized protective capabilities. NIJ.06 Level 4 Hard Armor Plates demonstrate the premium pricing associated with advanced ballistic protection technologies. The higher cost stems from intricate ceramic composition and rigorous manufacturing standards required to ensure consistent performance against high-velocity threats.

UHMWPE plates present a more cost-effective solution, with pricing typically between $100 and $300 per plate. Their economic advantage extends beyond initial purchase, offering reduced long-term maintenance expenses and enhanced durability. Budget-conscious buyers – including smaller law enforcement agencies, security firms, and civilian users – find these plates particularly attractive. The plates’ multi-hit capabilities and longer operational lifespan translate to more sustainable protection investments.

Key purchasing factors extend beyond pure cost considerations. Professionals must evaluate plate compatibility with existing carrier systems, NIJ protection ratings, weight constraints, and specific operational environments. Availability can vary significantly, with specialized plates often subject to production lead times and potential supply chain limitations. For tactical professionals and security-conscious individuals, the ultimate decision requires carefully weighing protection levels, budget constraints, and anticipated threat scenarios against the unique characteristics of ceramic and UHMW PE armor technologies.

Choose the Right Armor Plate for Your Mission

Understanding the differences between ceramic and UHMW PE armor plates is essential when your safety is on the line. Whether you need the unmatched initial impact defense of ceramic plates or the lightweight, multi-hit resilience of UHMW PE, finding gear that matches your specific threat environment and operational demands is critical. At AcelinkArmor.com, we know your challenge is balancing protection, comfort, and durability without compromise.

Explore our selection of NIJ Rated Level IV Armor Plates for high-threat scenarios or browse lighter options like the Level 3+ Ceramic Plate 10×12″ designed to boost mobility. Don’t settle for uncertainty when you can choose trusted solutions built to protect. Visit AcelinkArmor.com today to secure your armor plate and gain confidence on every mission.

Frequently Asked Questions

What are the main differences between ceramic and UHMW PE armor plates?

Ceramic armor plates are made from hard ceramic materials and provide superior initial strike protection, while UHMW PE plates are made from lightweight polymer fibers, offering excellent multi-hit capability and enhanced flexibility.

How do the weight and comfort compare between ceramic and UHMW PE plates?

Ceramic plates typically weigh between 5-7 lbs, providing robust protection but potentially leading to fatigue during extended wear. In contrast, UHMW PE plates weigh about 3-4 lbs, allowing for greater mobility and comfort without significant compromise on protection.

What is the multi-hit capability of ceramic versus UHMW PE plates?

Ceramic plates have limited multi-hit capability, as a single impact can compromise their structural integrity. UHMW PE plates excel in multi-hit scenarios, maintaining their protective performance after multiple ballistic impacts.

How do ceramic and UHMW PE plates perform in terms of durability and maintenance?

Ceramic plates are more fragile and require immediate replacement after any significant impact, while UHMW PE plates are more resilient, allowing for continued use after multiple hits, although they still need protection from UV exposure and extreme temperatures.

Recommended

- NIJ Rated Level IV Armor Plates – Ace Link Armor

- Level 3+ Ceramic Lightweight Plate 10×12″ – Ace Link Armor

- Level 3+ Ceramic Plate 10×12″ – Ace Link Armor

- NIJ.06 Level 4 Hard Armor Plates – Ace Link Armor