- Steel plates are the heaviest armor plates available on the market

- Steel plates impose the risk of spalling, which can be deadly.

- Steel armor plates restrict movement while in combat action

- What are ceramic armor plates made of?

- Why are ceramic plates named "composite plates"?

- What are the main types of ceramic plates?

- Can ceramic body armor stop the same threat as steel armor?

- What is the most affordable level IV ceramic plate?

- Do you need a special plate carrier for ceramic plates?

- Final Thoughts:

Armor plates are made from various different materials, and their construction can have a significant impact on their weight, durability, and performance on the field. The first thing that comes to mind when most people think of body armor plates is steel.

Steel body armor plates are quite common, and they are the most affordable option out there. This is mainly because steel body armor plates are much simpler to make than other kinds of armor plates, however, they also have several drawbacks, which diminish their tactical effectiveness on the field, and hence drive down their price.

So, in this post we will talk about the drawbacks of steel armor, and what the alternatives have to offer. This post will help you understand why steel body armor plates are so cheap, and why they aren’t very practical.

Steel plates are the heaviest armor plates available on the market

One of the main drawbacks of steel body armor plates is that they are very heavy. In many combat and tactical situations, operators have to wear their body armor for a very long time and walk long distances while carrying their gear.

Therefore, having the additional weight of a couple of super heavy steel body armor plates is not practical, and can really take the wind out of them. A standard level 3 steel plate can weigh between 5-7 lbs, whereas level 4 steel plates are so heavy that they aren’t even practical to make.

Steel plates impose the risk of spalling, which can be deadly.

Steel plates can also be dangerous in some scenarios. Though you can hit steel a lot of time with small calibers, and it won’t have any deformation that doesn’t mean these plates have an excellent multi-hit capability when used as body armor.

When rifle rounds hit a steel plate, they break into small fragments, which are deflected on the sides. These fragments can hit the people, sound you, or even deflect straight up towards your throat. This concept is called spalling. It can ruin your plate carrier and be very dangerous and deadly.

Therefore, any steel plate that is used for body armor comes with a rubberized coating on the strike face. This coating keeps the bullet fragments from deflecting from the plate, but even the best coatings can only do so for a few rounds. This is one of the main reasons why militaries don’t use steel plates.

Steel armor plates restrict movement while in combat action

Steel armor plates are also very hard and heavy, and they can significantly decrease a person’s movement and agility on the field. Steel body armor systems, with two plates, side plates, and tactical gear can easily weigh over 20-25 lbs, and caring that weight with a rifle, and other equipment makes soldiers slow on the battlefield. This is another reason why steel body armor systems are not viable for combat scenarios, even though they are very affordable and have a long shelf life.

What are ceramic armor plates made of?

Ceramic body armor plates are much more complicated to make than simple steel plates. A standard Ceramic body armor plate has two main parts. The strike face and the back plate. The strike face is made from small ceramic tiles, on a complete monolithic ceramic plate, whereas the back plate is made from PE or in some cases even soft Aramid armor fibers.

There are multiple ceramic materials that can be used to make the strike face of a ceramic body armor plate. For the most part, materials like Aluminum Oxide, Silicon Carbide, Boron Carbide, and Titanium Diboride are used to make ceramic body armor.

Why are ceramic plates named “composite plates”?

Ceramic plates usually aren’t made of ceramic materials alone. They have a ceramic strike face, which disperses the force of the bullet on a larger area and breaks it up, and they have a base plate, which can be made from UHMWPE.

Some ceramic armor systems also use a steel back plate, however, they can get quite heavy. Ceramic body armor plates with lightweight backing made from Ultra High Molecular Weight Polyethylene are the best options on the market.

What are the main types of ceramic plates?

Based on their shape, and the way they are used to make body armor, ceramic plates are of two tiles. Some ceramic plates have a one-piece Monolithic ceramic strike face, whereas others may have smaller separate ceramic tiles mounted on a PE back plate.

Smaller ceramic tiles don’t offer the same level of performance a monolithic ceramic plate provides. Mainly because a ceramic tile has a smaller area for the cracks to form and disperse the impact of the bullet. Moreover, in some cases, the bullet may make an impact exactly in between two tiles, decreasing the ballistic protection capabilities of your armor system. On the other hand, Monolithic ceramic body armor plates are much safer, however, they can’t take multiple hits as well as ceramic tiles.

Next up, the type of ceramic plates can also be differentiated by the type of ceramic material used to make them. For instance, materials like Aluminum Oxide, Silicon Carbide, Boron Carbide, and Titanium Diboride can be used to make ceramic plates. However, Aluminum Oxide and Silicon Carbide are the two most common materials used to make ceramic body armor. Both materials can be used to make ceramic body armor, however, Silicon Carbide plates are better suited for stopping large rounds.

Can ceramic body armor stop the same threat as steel armor?

Yes, ceramic armor plating can stop the same level of threats as steel plates. The ability of body armor to stop bullets from penetrating isn’t determined by the material used to make it. In the US, body armor is regulated by the National Institute of Justice, and they have set two threat levels for rifle caliber.

These are level III and level IV. A level III plate is rated to stop the most popular intermediate rifle calibers up to .308 Winchester or 7.62xx51mm NATO, regardless of the material it is made of. So, a level III steel body armor plate, and a level III ceramic plate will offer the same level of protection.

However, you can say that Ceramic armor is better suited to stop bullets, because level IV armor plates, rated to stop Armor piercing calibers up to a 30.06 Springfield Armor piercing round, can only be made with a ceramic strike face.

What is the most affordable level IV ceramic plate?

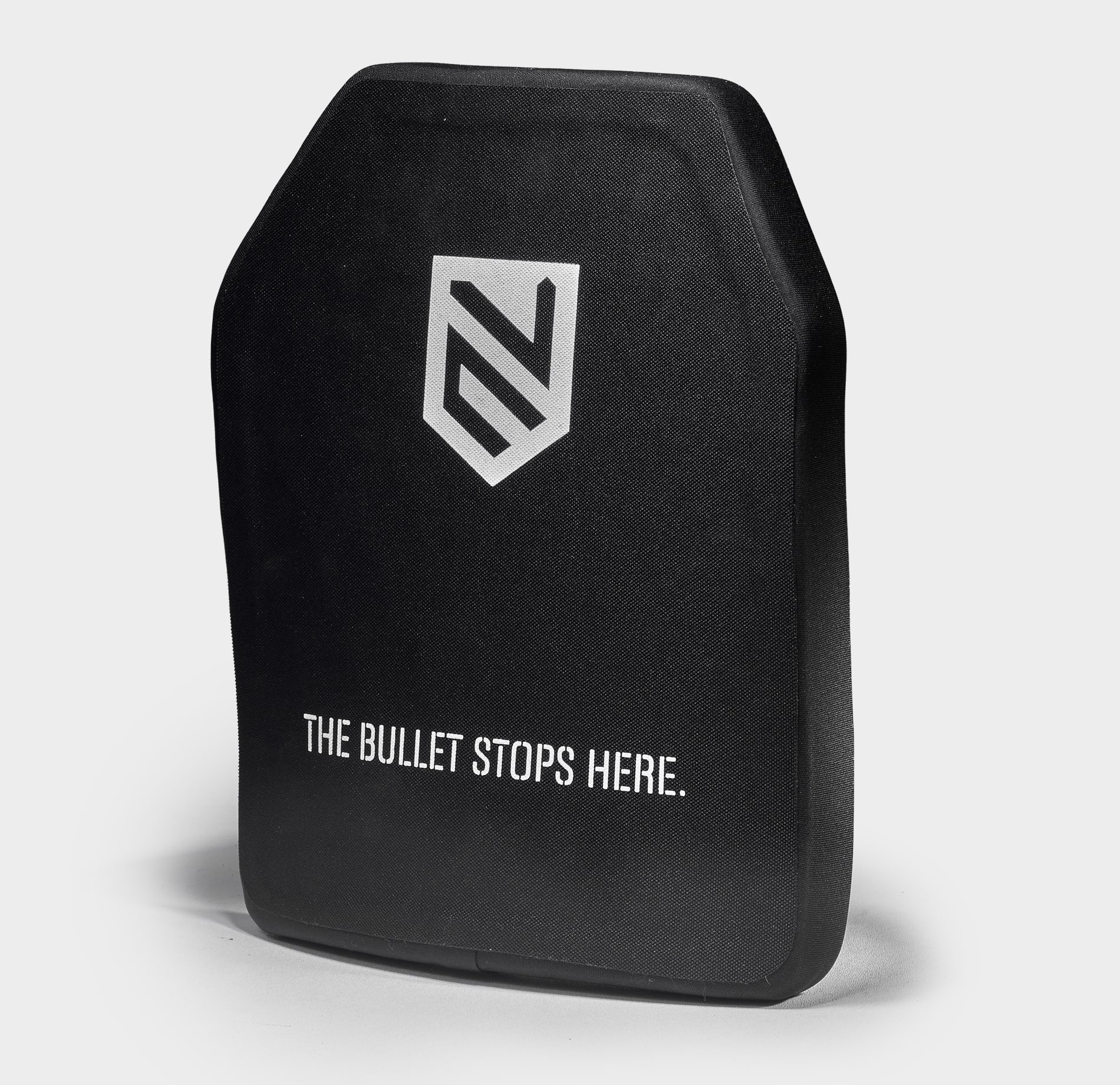

If you are looking for affordable, and high-quality ceramic body armor plates, the Level IV Plate from AceLink Armor is the best possible option. These PE + Ceramic Composite body armor plates are very lightweight, weighing as little as 6.1 pounds, and offer multiple hit protection against most Battle rifle rounds up to an Armor Piercing 30.06 Springfield.

The AceLink level IV ceramic body armor plates have a unique multi-curve design, which allows them to fit the contour of the wearer’s body, and be more comfortable than traditional level IV plates.

Do you need a special plate carrier for ceramic plates?

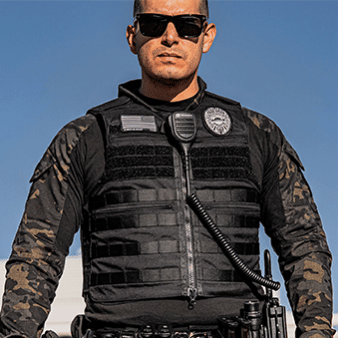

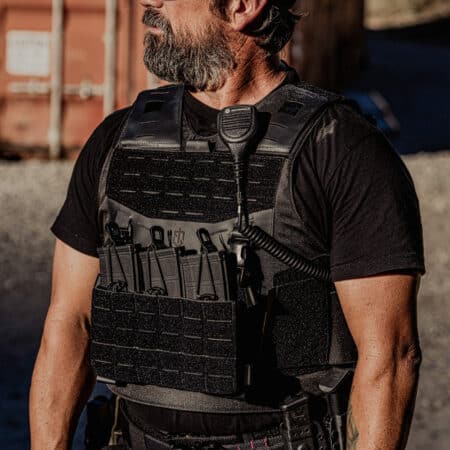

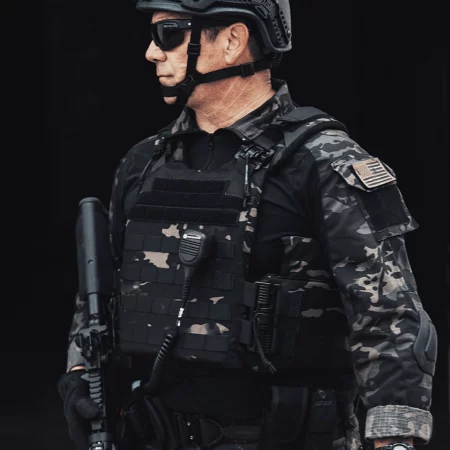

No, almost all body armor manufacturers follow the same sizes when making their body armor plates. Both steel and ceramic body armor plates are made to be the same size and can fit in any plate carrier. AceLink armor has a wide range of impressive plate carriers, which are ideal for any Ceramic body armor plates.

Final Thoughts:

So, in conclusion, Steel armor plates can be quite cheap, and many new shooters tend to prefer them over ceramic armor plates. However, as we have mentioned in this post, there is a reason why these plates are so cheap. Ceramic armor plates are a much better option. They are safer and much lighter than steel plates as well, making them perfect for use in any combat scenario.