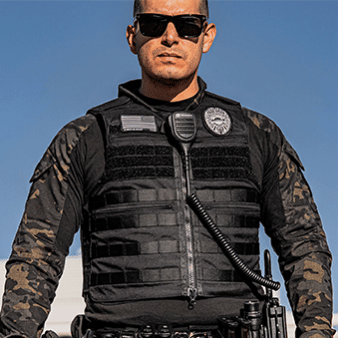

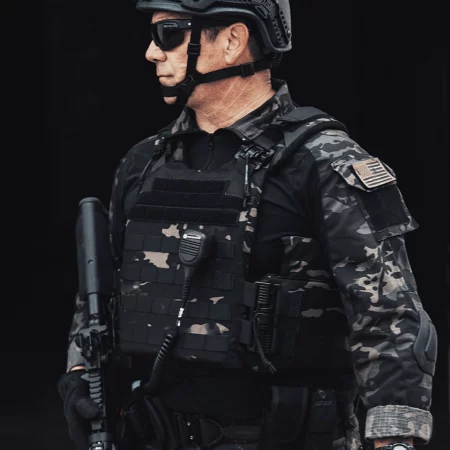

Every day, millions of police officers, soldiers, and even civilians around the world have to survive, and function in hostile environments. They are in constant danger of being attacked and have to take their personal protection very seriously. Therefore, these people need to use bulletproof vests or ballistic body armor plates with plate carriers, which keeps them safe in case they get shot at.

Over the past few decades, body armor technology has evolved significantly. Ballistic plates have become standard for military personnel and can be used by civilians as well. So, today we will talk about the future of personal protection, and why the near future will be dominated by ceramic armor plates

The limitations of traditional body armor materials

Traditionally, body armor has mostly been made from metal. These days, Materials like Kevlar are used to make soft body armor, however, steel hard armor plates are still quite common. Metal armor has certain limitations, that made me believe that it won’t be around for too long.

Steel armor plates are very heavy, and more importantly, they can be dangerous. Steel plates can cause Spalling, which is a very dangerous phenomenon. You see, when a bullet strikes a steel armor plate, it breaks up into fragments. These fragments can then ricochet off the plate, and injure the person wearing body armor, or the people around them.

Most steel armor plates on the market these days use a rubberized coating on their steel plates, which is meant to catch these fragments. This coating can be effective, however, after a few hits, it breaks off, and makes the plate quite dangerous.

The benefits of ceramic body armor plates

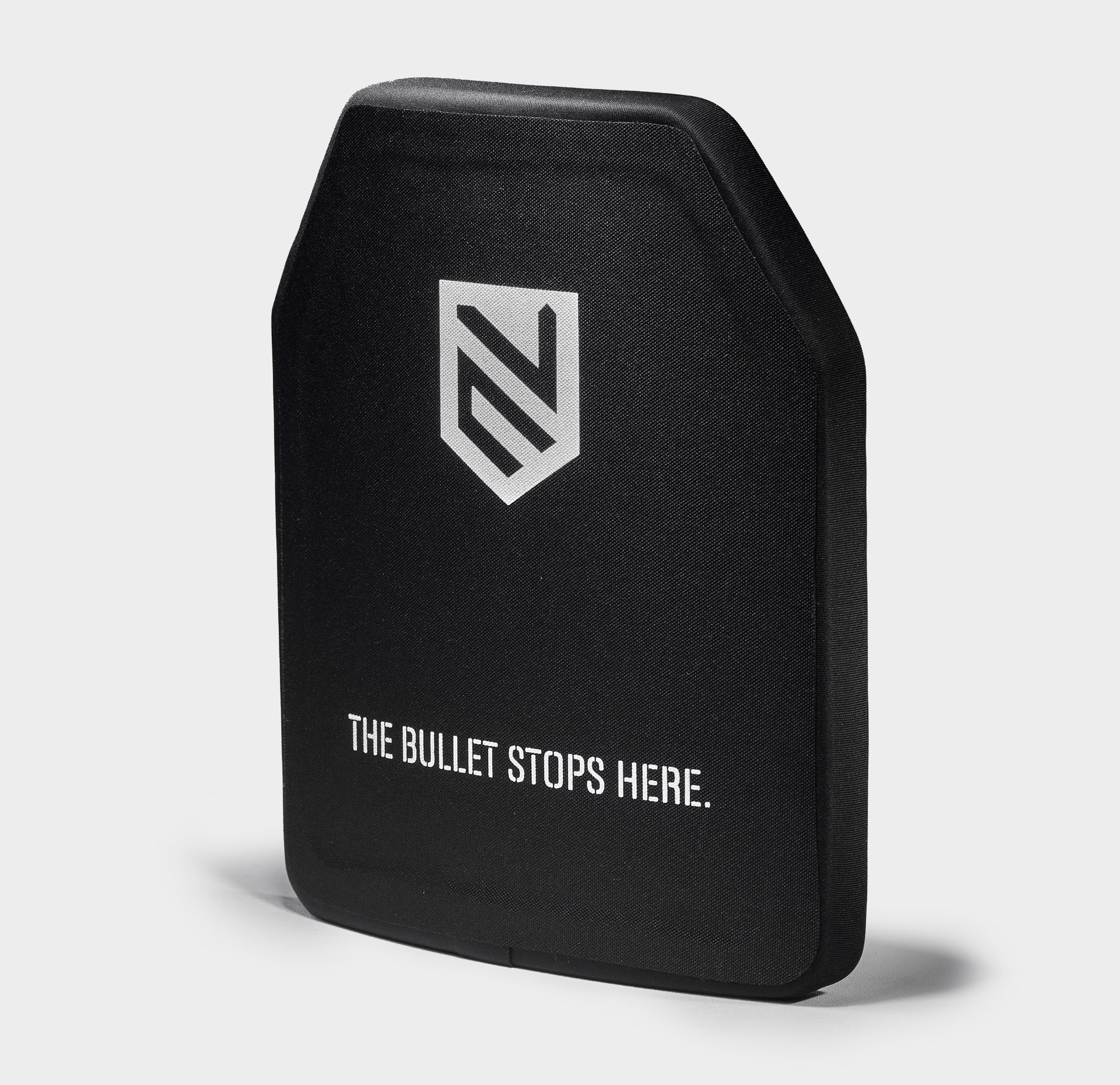

Ceramic plates are the best option when it comes to protection for high-caliber rounds. Though other materials are being used to make armor plates, Ceramic body armor plates have some advantages that can’t be matched.

Lightweight and durable:

Ceramic body armor plates have an excellent weight-to-effectiveness ratio. For instance, a level iv body armor plate could be made from steel, but it would be way too heavy to be practical, whereas a level iv body armor plate made from ceramics is significantly lighter.

There are body armor materials like PE, which are lighter than ceramics, however, polyethylene armor does not offer the same level of protection. A level iv body armor plate can be made from polyethylene, however, some ultra-lightweight level iv body armor plates do use PE backings for better performance.

Effective against high-velocity projectiles:

When it comes to penetrating body armor, the speed of the bullet is more important than the size, and ceramic body armor is the best for stopping high-velocity rounds. On steel plates, high-velocity rounds tend to ricochet, whereas ceramic plates absorb their impact more effectively and safely.

Level iv body armor plates, which are made from ceramics, can stop up to 30.06 armor-piercing rounds.

Multi-hit capabilities:

In all honesty, Ceramic armor plates aren’t the best at taking multiple hits, however, they can still handle multiple rounds, especially if they don’t hit at the same spot. When a ceramic plate is hit with a bullet, it can start to crack, and this significantly decreases its protective capabilities.

However, most ceramic body armor plates come with a sort of backing, which can be made from Kevlar, PE, or other materials. This backing makes sure that the ceramic plate doesn’t shatter as it is hit. This allows them to take multiple rounds safely.

On the other hand, a steel plate may be able to take more rounds without being damaged, however, as soon as its rubber coating falls off, it increases the risk of spalling. Therefore, I believe that Ceramic armor offers more reliable and effective multi-hit capabilities.

The drawbacks of ceramic armor plates

Expensive compared to other materials

Ceramic armor plates tend to be more expensive than other plates in the long run. Ballistic plates made from other materials like steel, and PE have a longer shelf life. They can last up to ten years if kept safely, however, as we already know, steel plates can be too heavy, and PE plates alone don’t provide the armor level that plates made from ceramics do.

Ceramic armor plates have a shelf life of about 5 years, and after that, they need to be replaced, moreover, if there are not even once, you can’t rely on them for protection anymore.

Fragile and susceptible to cracking under extreme conditions

A ceramic plate may be able to stop a high-velocity bullet, but it can easily get damaged if it is dropped. Moreover, extreme conditions like excessive moisture can also damage the integrity of these plates. Therefore, if you choose to use a ceramic armor plate you will need to pay extra attention to its storage and maintenance.

The future of ceramic armor plates

Ceramic body armor has been around for a very long time. Back in the 70s and 80s, it was only used to make armored helicopter seats. Over the years, lightweight ceramic armor panels were used on ground attack aircraft, and armored personnel carriers as well.

As body armor technically improved, and manufacturers improved the properties of ceramic materials themselves, lighter and stronger ceramic armor became easier to develop, and this is where ceramic body armor plates were made.

The most common ceramic materials used for body armor applications these days are alumina, boron carbide, silicon carbide, and titanium diboride. These materials have a lower Ariel Density than old ceramics, and therefore, they can be more weight efficient.

You can get some standalone ceramic plates for lower protection levels, however, for level 4 body armor plates, a composite of ceramics and other materials is used. In the future, as we discover and develop stronger ceramic materials, with lower ariel density, we can make lighter and thinner ceramic plates. Some companies are also developing Continuous metal fiber-reinforced silicon carbide ceramic, which allows Ceramic plates to not be completely pulverized to dust when hit by a shaped charge. This type of armor will definitely be used on Armored Personnel Vehicles and Tanks.

Moreover, advancements in other aspects of body armor may also affect the overall effectiveness of ceramic armor plates, and how they are used on the field. For instance, plate carriers with built-in body armor panels are used by the US military. This IOTV plate carrier has an internal Kevlar lining, and therefore, it can increase the protection capabilities of an ESAPI Ceramic plate. Similarly, when more advanced plate carriers are made with better protection capabilities, lighter ceramic plates will be used.

Conclusion

So, Ceramic body armor plates are easily the most effective form of body armor available on the market today. Though wearing soft body armor vests is great if you are looking to protect your vital organs against pistol rounds when it comes to rifle rounds, Ceramic plates offer superior protection than steel plates.

Ceramic body armor plates are also quickly becoming a standard for most militaries in the world, and over the coming years, as they are improved, they may even become the standard form of body armor on the market.