- Table of Contents

- Key Takeaways

- Ceramic Plates in Ballistic Armor: Core Principles

- Material Composition and Ballistic Performance

- Edge Protection: Types and Impact on Durability

- Understanding Drop Tests and Industry Standards

- Selecting the Right Ceramic Plate for Protection

- Enhance Your Protection with Advanced Ceramic Plates from AcelinkArmor

- Frequently Asked Questions

- Recommended

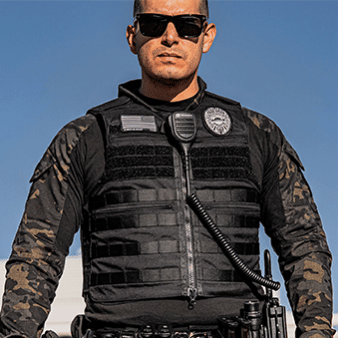

Ceramic plates have transformed body armor by combining science and innovation into every protective layer. Nearly 80 percent of law enforcement and military body armor now incorporates ceramic components for enhanced protection. This matters because the right armor can mean the difference between life and death in high-risk situations. By understanding the core principles behind ceramic plates, you gain insight into why these materials deliver advanced strength while remaining light and adaptable for real-world threats.

Table of Contents

- Ceramic Plates In Ballistic Armor: Core Principles

- Material Composition And Ballistic Performance

- Edge Protection: Types And Impact On Durability

- Understanding Drop Tests And Industry Standards

- Selecting The Right Ceramic Plate For Protection

Key Takeaways

| Point | Details |

|---|---|

| Advanced Material Science | Ceramic plates utilize innovative materials and engineering principles for superior ballistic performance. |

| Energy Management Systems | The design of ceramic armor focuses on effective energy absorption and dissipation to enhance protection. |

| Critical Edge Protection | Robust edge reinforcement enhances durability and prevents vulnerabilities at structural boundaries. |

| Rigorous Testing Standards | Comprehensive drop tests ensure compliance with standards and validate the effectiveness of ceramic plates across various conditions. |

Ceramic Plates in Ballistic Armor: Core Principles

Ceramic plates represent a groundbreaking advancement in personal armor technology, offering unparalleled protection through innovative material science. According to ceramics.org, the effectiveness of ceramic armor hinges on complex factors like hardness, toughness, and intricate microstructural properties that determine its ballistic performance.

Ceramic materials provide extraordinary advantages in protective gear due to their unique physical characteristics. As research from nap.nationalacademies.org demonstrates, these advanced materials deliver superior hardness and low density while maintaining exceptional compressive strength. When strategically combined with polymers or metal composites, ceramic plates can effectively dissipate the kinetic energy generated by incoming projectiles.

The core performance of ceramic armor plates depends on several critical engineering principles:

- Energy Absorption: Ceramics fracture and disintegrate upon projectile impact, converting destructive kinetic energy into controlled material breakdown

- Weight Optimization: Significantly lighter compared to traditional metal armor plates

- Penetration Resistance: Extremely hard surface disrupts and fragmentizes incoming high-velocity projectiles

Microstructural damage mechanisms play a pivotal role in ceramic plate performance. Sophisticated engineering techniques like controlling plastic deformation and managing microcrack initiation enable manufacturers to design progressively more effective ballistic protection systems. Level 3+ Ceramic Lightweight Plate 10×12″ represents a prime example of these advanced protective technologies, integrating cutting-edge material science into practical personal defense solutions.

Material Composition and Ballistic Performance

Ceramic armor composition represents a complex engineering challenge that directly impacts protective capabilities. According to research from mdpi.com, polyurea-reinforced ceramic/metal armor systems demonstrate remarkable potential for enhanced ballistic performance by strategically absorbing energy during impact, resulting in significantly higher mass efficiency compared to traditional ceramic armor configurations.

The intricate science behind ceramic armor involves precisely engineered material interactions. Studies from gywlxb.cn reveal that optimizing ceramic ball size and arrangement within metal composite structures can dramatically improve overall ballistic resistance. This approach transforms armor from a simple protective barrier into a sophisticated energy management system.

Key factors influencing ceramic armor performance include:

- Material Hardness: Determines initial projectile interaction and fragmentation

- Energy Dissipation: Ability to convert kinetic impact into controlled material breakdown

- Structural Integrity: Maintaining protective capabilities after initial impact

Advanced manufacturing techniques now allow for multilayered ceramic composites that can adapt and respond to different ballistic threats. By integrating materials with complementary properties, engineers create armor systems that provide unprecedented protection while maintaining critical weight and mobility requirements. Understanding UHMW PE vs. Aramid for Ballistic Application offers deeper insights into these sophisticated material selection strategies that push the boundaries of personal protective equipment design.

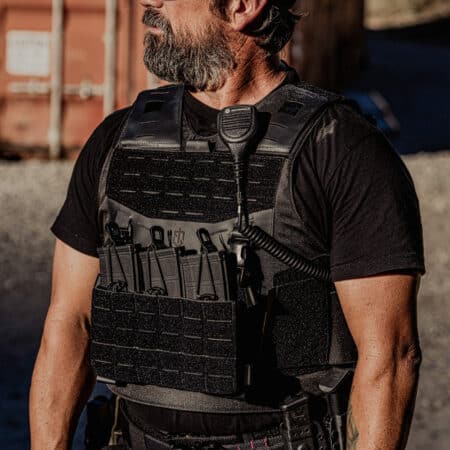

Edge Protection: Types and Impact on Durability

Edge protection is a critical yet often overlooked aspect of ceramic armor design that significantly influences long-term performance and reliability. According to research from scientific.net, the choice of adhesives in ceramic-metal composite armor plays a pivotal role in determining dynamic compressive strength and overall ballistic performance, making edge construction a fundamental engineering challenge.

Understanding the intricate failure mechanisms at armor edges requires deep material science expertise. mdpi.com research on ZrO2 ceramic composite projectile impacts reveals complex interaction dynamics that expose the vulnerabilities of ceramic armor edges. These studies demonstrate that microscopic damage initiation often begins at structural boundaries, underscoring the importance of robust edge reinforcement strategies.

Critical considerations for effective edge protection include:

- Material Bonding: Ensuring seamless integration between ceramic and metal components

- Stress Distribution: Preventing localized stress concentration

- Crack Propagation Resistance: Minimizing structural vulnerabilities

Engineering solutions for enhanced edge durability have evolved to include advanced techniques like:

- Specialized polymer reinforcement

- Precision-engineered metal interface layers

- Microstructural boundary modifications

These innovations transform armor edges from potential weak points into strategically reinforced zones of increased resilience.

Level 3+ Ceramic Multi-curve Plate 10×12″ exemplifies how modern manufacturing techniques can integrate sophisticated edge protection mechanisms, ensuring maximum structural integrity under extreme ballistic challenges.

Level 3+ Ceramic Multi-curve Plate 10×12″ exemplifies how modern manufacturing techniques can integrate sophisticated edge protection mechanisms, ensuring maximum structural integrity under extreme ballistic challenges.

Understanding Drop Tests and Industry Standards

Drop tests represent a critical evaluation method for ceramic armor plates, simulating real-world impact scenarios and assessing structural integrity under extreme conditions. According to research from nap.nationalacademies.org, comprehensive testing methodologies are essential for ensuring compliance with rigorous industry standards and validating the performance of protective equipment across diverse operational environments.

The American Ceramic Society ceramics.org emphasizes that standardized drop testing goes far beyond simple impact assessments. These sophisticated evaluations probe the microstructural integrity of ceramic materials, examining how plates respond to sudden mechanical stress, potential mishandling, and unexpected environmental challenges that could compromise protective capabilities.

Key aspects of professional drop testing include:

- Height Variations: Simulating drops from different elevations

- Surface Condition: Testing impact on multiple terrain types

- Temperature Range: Evaluating performance across extreme environmental conditions

Drop test protocols typically involve:

- Controlled height drops onto hard surfaces

- Angular impact assessments

- Repeated stress evaluations

- Post-impact structural integrity analysis

Advanced testing methodologies now incorporate sophisticated measurement techniques that provide granular insights into material performance. NIJ Rated Level IV Armor Plates demonstrate how rigorous testing translates directly into enhanced protection, ensuring that each plate meets the most demanding professional standards for reliability and durability.

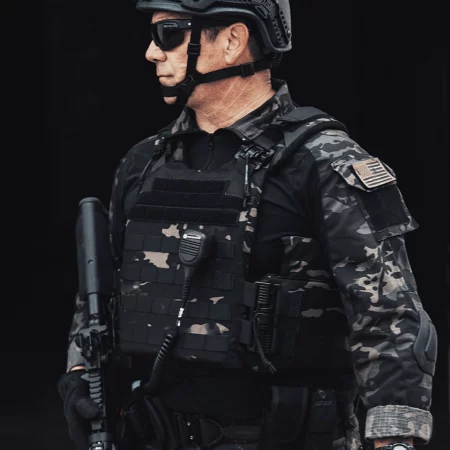

Selecting the Right Ceramic Plate for Protection

Ceramic plate selection demands a comprehensive understanding of complex protective requirements and material performance characteristics. According to guidelines from nap.nationalacademies.org, choosing the optimal ceramic plate involves carefully evaluating material properties, composite design, and strict compliance with established military protection standards.

The American Ceramic Society ceramics.org emphasizes that material selection extends beyond simple protection metrics. Processing methods, cost-effectiveness, and achieving the critical balance between hardness and toughness are fundamental considerations that directly impact a ceramic plate’s operational effectiveness.

Critical selection criteria include:

- Protection Level: NIJ rating and verified ballistic performance

- Weight Considerations: Balancing protection with mobility

- Environmental Durability: Resistance to temperature variations

- Structural Integrity: Long-term performance under stress

Professional ceramic plate selection requires evaluating multiple interconnected factors:

- Threat assessment for specific operational environments

- Required mobility and load-bearing capabilities

- Budget constraints

- Anticipated usage conditions

For professionals seeking precision-engineered protection, NIJ.06 Level 4 Hard Armor Plates represent a benchmark in advanced ceramic plate technology, offering comprehensive protection tailored to demanding tactical requirements.

Enhance Your Protection with Advanced Ceramic Plates from AcelinkArmor

Understanding the critical role of material composition, edge protection, and rigorous drop tests is essential when choosing ceramic armor plates that truly safeguard your life. The challenges of finding plates that combine lightweight durability with maximum ballistic resistance are real. You need gear engineered to absorb impact energy efficiently while maintaining integrity after sudden shocks or edge stress. At AcelinkArmor, we address these concerns head-on by offering expertly designed ceramic plates that meet and exceed strict NIJ standards.

Explore our wide range of Level 3+ Ceramic Lightweight Plates and Level 3+ Ceramic Multi-curve Plates that feature advanced edge reinforcement and proven ballistic performance. Protect yourself with confidence because every plate undergoes intense drop and impact testing to guarantee durability in critical moments. Stay one step ahead of threats by choosing reliable armor from the trusted selection at AcelinkArmor.com.

Ready to upgrade your ballistic protection with industry-leading ceramic armor plates designed for professional use and serious personal defense? Visit AcelinkArmor.com now and take action to secure your safety before the next call comes.

Frequently Asked Questions

What are the key benefits of ceramic plates in ballistic armor?

Ceramic plates provide exceptional hardness, low density, and outstanding energy absorption, making them effective at dissipating kinetic energy from projectiles while offering lightweight protection.

How does edge protection enhance the durability of ceramic armor plates?

Edge protection is crucial for maintaining structural integrity, as it prevents crack propagation and ensures strong material bonding between ceramic and metal components, enhancing overall ballistic performance.

What role do drop tests play in evaluating ceramic armor plates?

Drop tests simulate real-world impact scenarios to assess the structural integrity and performance of ceramic plates under various conditions, ensuring compliance with industry standards and reliability in protective capabilities.

How should I select the right ceramic plate for my protection needs?

Selecting a ceramic plate involves considering the protection level (NIJ rating), weight, environmental durability, and specific threat assessments to ensure optimal performance in your operational environment.

Recommended

- Level 3+ Ceramic Multi-curve Plate 10×12″ – Ace Link Armor

- Level 3+ Ceramic Lightweight Plate 10×12″ – Ace Link Armor

- Level 3+ Ceramic Plate 10×12″ – Ace Link Armor

- NIJ Rated Level IV Armor Plates – Ace Link Armor