- Table of Contents

- Quick Summary

- What is UHMW PE vs. Aramid in Ballistics?

- Why Material Choice Matters for Ballistic Protection

- How UHMW PE and Aramid Work in Armor Systems

- Comparative Strengths and Weaknesses of UHMW PE and Aramid

- Real-World Applications of UHMW PE vs. Aramid Gear

- Discover the Right Ballistic Protection for Your Mission

- Frequently Asked Questions

- Recommended

Ballistic armor might sound like something out of an action movie, but the science behind it has changed the real world. Think about this. Materials like UHMW PE absorb impact energy so well that they can stop high-velocity bullets while weighing up to 50 percent less than steel plates. When buying a bulletproof vest, most people focus on the strength of the material, yet the real difference comes from how smart design and the right choice between UHMW PE and aramid can mean the difference between safety and vulnerability.

Table of Contents

- What Is UHMW PE And Aramid In Ballistics?

- Why Material Choice Matters For Ballistic Protection

- How Uhmw Pe And Aramid Work In Armor Systems

- Comparative Strengths And Weaknesses Of Uhmw Pe And Aramid

- Real-World Applications Of Uhmw Pe Vs. Aramid Gear

Quick Summary

| Takeaway | Explanation |

|---|---|

| UHMW PE offers superior lightweight protection. | Its excellent strength-to-weight ratio minimizes mobility impacts while providing effective ballistic resistance. |

| Aramid fibers excel in multi-hit scenarios. | These fibers maintain integrity and protective capabilities after repeated impacts, making them ideal for soft body armor. |

| Material selection impacts survival probability. | Choosing the right ballistic material is crucial for maximizing protection against potential threats in life-or-death situations. |

| Both materials have unique capabilities. | UHMW PE is best for high-velocity projectiles, while Aramid fibers are effective for versatile tactical applications. |

| Understanding environmental effects is essential. | Performance can vary with environmental factors; UHMW PE is moisture-resistant while Aramid fibers resist broader temperature variations. |

What is UHMW PE vs. Aramid in Ballistics?

Ballistic protective materials represent a critical technological frontier in personal safety and defense equipment. UHMW PE (Ultra High Molecular Weight Polyethylene) and Aramid fibers are two advanced materials that have revolutionized body armor and protective gear design, each offering unique characteristics that make them essential in modern ballistic applications.

Understanding Material Composition

UHMW PE is a synthetic thermoplastic polymer renowned for its exceptional molecular weight and extraordinary mechanical properties. In ballistic contexts, this material demonstrates remarkable strength-to-weight ratios, providing superior impact resistance while remaining incredibly lightweight. Its molecular structure allows energy dispersion across a broader surface area, effectively reducing the potential for projectile penetration.

Our comprehensive body armor guide explores how these material characteristics translate into real-world protection strategies. Aramid fibers, by contrast, represent a class of synthetic materials like Kevlar and Twaron, characterized by their high tensile strength and exceptional thermal stability. These para-aramid polymers are woven into tight, intricate patterns that create a dense, energy-absorbing matrix capable of catching and dissipating ballistic impacts.

UHMW PE vs. Aramid in Ballistic Protection

Both materials excel in different protective scenarios. UHMW PE offers superior performance against high-velocity projectiles, maintaining structural integrity under extreme stress. Its low density enables the creation of lightweight armor plates that do not compromise mobility. Aramid fibers, conversely, provide exceptional multi-hit capabilities and resistance to repeated impacts, making them ideal for soft body armor and tactical applications.

Key performance attributes include:

- Extraordinary energy absorption capabilities

- Minimal weight penalty for protection levels

- High resistance to environmental degradation

- Adaptable to various protective gear configurations

Understanding these materials requires recognizing their complementary nature in ballistic protection strategies, where each material brings unique advantages to personal safety equipment design.

To help you compare the essential differences between UHMW PE and Aramid fibers in ballistic protection, the following table summarizes their key characteristics side by side.

| Feature | UHMW PE | Aramid Fibers |

|---|---|---|

| Material Type | Synthetic thermoplastic polymer | Synthetic para-aramid polymer |

| Strength-to-Weight Ratio | Extremely high (lightweight) | High, but heavier than UHMW PE |

| Ballistic Resistance | Excellent, especially against high-velocity rounds | Excellent, especially for soft body armor |

| Multi-Hit Capability | Moderate | Superior (retains protection after multiple hits) |

| Environmental Resistance | Outstanding moisture resistance; sensitive to high heat | Good moisture resistance and heat stability |

| Flexibility | Lower (rigid plates) | High (used in flexible vests and sleeves) |

| Typical Applications | Hard armor plates, helmets | Soft body armor, vehicle and aircraft panels |

Why Material Choice Matters for Ballistic Protection

In the critical domain of personal protection, selecting the appropriate ballistic material is not merely a technical decision but a life-saving calculation. Material selection directly influences an individual’s survival probability when confronted with potential ballistic threats, making it a paramount consideration in body armor design and implementation.

Performance Under Dynamic Threat Conditions

Ballistic materials must perform consistently across diverse threat scenarios, which requires understanding their unique energy absorption and dispersion characteristics. According to defense research on protective materials, different materials react distinctly when encountering high-velocity projectiles, impacting their overall protective efficacy. The molecular structure and mechanical properties determine how effectively a material can mitigate kinetic energy transfer, preventing potential traumatic injury.

Critical Selection Parameters

Selecting optimal ballistic protection involves evaluating multiple interconnected parameters that extend beyond simple impact resistance. Comprehensive material assessment requires analyzing:

- Weight and mobility implications

- Multi-hit durability

- Environmental resistance

- Long-term material degradation potential

- Cost-effectiveness of protection

Level 3+ Ceramic Plate 10×12″ represents an example where advanced material engineering translates into superior protective capabilities. Professional operators and civilian defenders must recognize that material choice directly correlates with survival probability, making informed selection crucial.

For quick reference, the table below outlines the most important factors to consider when choosing between UHMW PE and Aramid for ballistic protection systems.

| Selection Parameter | UHMW PE | Aramid Fibers |

|---|---|---|

| Weight/Mobility | Very lightweight, enhances mobility | Lightweight, slight mobility trade-off |

| Multi-Hit Durability | Moderate | High |

| Environmental Resistance | Excellent against moisture, less heat stable | Stable across wide temperature range |

| Long-Term Durability | Good, may degrade with high heat | Excellent, resists aging and degradation |

| Cost-Effectiveness | Often higher cost | Moderately priced |

Ultimately, ballistic material selection represents a complex optimization challenge where mechanical engineering, material science, and human protection converge to create life-saving technologies that can mean the difference between vulnerability and security.

How UHMW PE and Aramid Work in Armor Systems

Understanding the intricate mechanics of ballistic protection materials requires a deep dive into their molecular and structural interactions with high-velocity projectiles. Armor systems leverage the unique properties of UHMW PE and Aramid fibers to create sophisticated protective barriers that can arrest and dissipate dangerous kinetic energy.

Molecular Energy Dissipation Mechanisms

Understanding Body Armor Material Types reveals the nuanced ways these materials counteract ballistic threats. According to advanced materials research, UHMW PE functions through an extraordinary molecular structure that allows rapid and widespread energy distribution. When a projectile impacts the material, its long polymer chains stretch and realign, effectively capturing and spreading the kinetic force across a broader surface area, minimizing localized damage.

Structural Response and Impact Mitigation

Aramid fibers employ a fundamentally different approach to threat mitigation. These high-performance polymers are woven into intricate, tightly interlocked patterns that create a dynamic energy absorption matrix. Upon projectile impact, the fibers stretch and deform, converting kinetic energy into molecular movement and heat, progressively slowing and eventually stopping the incoming threat.

Key performance dynamics include:

- Instantaneous energy redirection

- Molecular deformation without catastrophic failure

- Minimal structural compromise

- Rapid energy dissipation across the material

The synergistic potential of these materials becomes evident when understanding how their distinct characteristics complement each other. While UHMW PE offers superior lightweight protection with exceptional energy dispersion, Aramid fibers provide remarkable tensile strength and multi-hit capability, creating a comprehensive defensive strategy that adapts to varied threat scenarios.

Comparative Strengths and Weaknesses of UHMW PE and Aramid

Ballistic material performance represents a nuanced landscape where each material brings distinctive advantages and limitations. Understanding these characteristics is crucial for selecting the most appropriate protection strategy in diverse operational environments.

Performance Under Environmental Challenges

According to defense research on protective materials, environmental factors play a significant role in material effectiveness. UHMW PE demonstrates exceptional performance in scenarios requiring lightweight protection, with superior buoyancy and resistance to moisture. However, its vulnerability to high-temperature environments poses potential limitations. Aramid fibers, conversely, maintain consistent protective capabilities across broader temperature ranges, offering more stable performance in extreme conditions.

Structural and Mechanical Trade-offs

Mechanical properties reveal critical differences between these materials. UHMW PE excels in weight reduction and energy dispersion, making it ideal for applications prioritizing mobility and minimal burden. Its molecular structure allows for remarkable impact absorption with minimal material thickness. Aramid fibers, however, provide superior tensile strength and multi-hit resistance, creating more robust protective layers that can withstand repeated ballistic impacts.

Key comparative characteristics include:

- Weight efficiency

- Temperature stability

- Impact absorption capacity

- Long-term material durability

- Manufacturing complexity

- Cost-effectiveness

Bulletproof Armor Insert 11×14″ Aramid Flexcore exemplifies how material science translates theoretical advantages into practical protective solutions. The selection between UHMW PE and Aramid ultimately depends on specific operational requirements, threat scenarios, and individual protection priorities.

Real-World Applications of UHMW PE vs. Aramid Gear

Tactical protection technologies represent a critical intersection of material science and human safety, with UHMW PE and Aramid emerging as pivotal materials across diverse operational environments. Understanding their practical deployment illuminates the sophisticated strategies behind modern protective equipment.

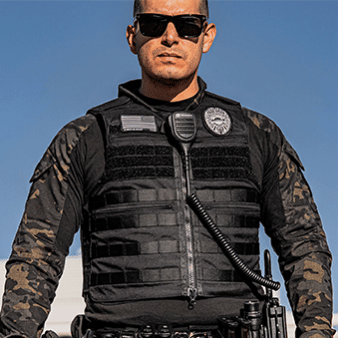

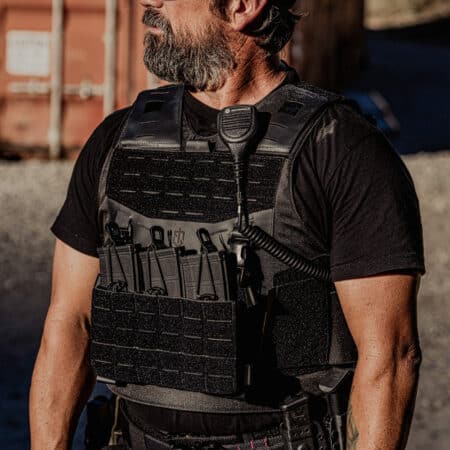

Law Enforcement and Security Sector Applications

According to forensic protective equipment research, aramid remains the cornerstone of traditional soft body armor used by police and security professionals. These materials excel in creating flexible, concealable vests that provide essential protection against handgun threats while maintaining mobility. UHMW PE, by contrast, has revolutionized hard armor plate technology, offering unprecedented weight reduction without compromising ballistic resistance.

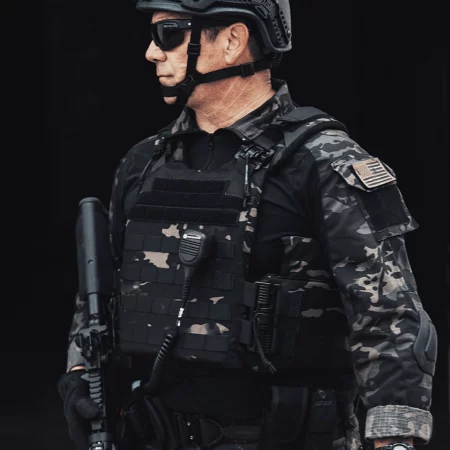

Military and Specialized Tactical Gear

In high-intensity operational contexts, material selection becomes a matter of life and death. Specialized tactical gear leverages the unique properties of both materials to create comprehensive protection systems. UHMW PE dominates in helmet construction and external armor plates, providing exceptional impact resistance with minimal weight penalty. Aramid fibers find critical applications in vehicle armor, helicopter panels, and protective sleeves where flexibility and multi-hit capability are paramount.

Key deployment scenarios include:

- Urban law enforcement protective vests

- Military body armor systems

- High-risk security personnel equipment

- Emergency response team gear

- Specialized maritime and aerospace protection

Level 3+ Ceramic Multi-curve Plate 10×12″ exemplifies how advanced materials integrate to create next-generation protective solutions. The selection between UHMW PE and Aramid ultimately depends on specific mission parameters, threat environments, and the precise balance between protection, mobility, and operational flexibility.

Discover the Right Ballistic Protection for Your Mission

Choosing between UHMW PE and Aramid materials is more than a technical choice—it is about confidence when it counts, and peace of mind in critical moments. If you are uncertain how ballistic material choices impact your safety, or if you feel overwhelmed by technical specifications, you are not alone. The article explained that factors like energy absorption, weight, multi-hit durability, and environmental resistance can make all the difference in real-life situations. Your personal protection should never leave you second-guessing its effectiveness under pressure.

Let AcelinkArmor.com help you make an informed decision with gear that matches your unique needs. Whether you need lightweight mobility using advanced UHMW PE or multi-hit strength and heat stability with Aramid, explore our full range of body armor solutions designed for law enforcement, tactical professionals, and security-conscious civilians. Dive deeper into our informational resources to turn knowledge into protection you can trust. Ready to upgrade or build your custom setup? Visit AcelinkArmor.com today and safeguard your next mission with proven ballistic technology that will not let you down.

Frequently Asked Questions

What is UHMW PE and why is it used in ballistic protection?

UHMW PE, or Ultra High Molecular Weight Polyethylene, is a synthetic thermoplastic polymer known for its high strength-to-weight ratio and exceptional impact resistance, making it ideal for lightweight ballistic armor.

How do Aramid fibers compare to UHMW PE in terms of ballistic protection?

Aramid fibers, like Kevlar, provide high tensile strength and multi-hit capability, making them suitable for soft body armor. In contrast, UHMW PE excels against high-velocity projectiles with superior weight efficiency.

What are the critical factors to consider when choosing ballistic materials?

Key factors include weight and mobility, multi-hit durability, environmental resistance, long-term degradation potential, and cost-effectiveness.

Can UHMW PE and Aramid fibers be combined in ballistic armor systems?

Yes, combining UHMW PE and Aramid fibers leverages their unique strengths, resulting in enhanced protective capabilities that can withstand diverse threats while maintaining mobility.

Recommended

- Level 3+ Ceramic Plate 10×12″ – Ace Link Armor

- Level 3+ Ceramic Multi-curve Plate 10×12″ – Ace Link Armor

- Level 3+ Ceramic Lightweight Plate 10×12″ – Ace Link Armor

- NIJ.06 Level 4 Hard Armor Plates – Ace Link Armor