- Table of Contents

- Quick Summary

- Step 1: Inspect for Visible Damage on Ballistic Panels

- Step 2: Ballistic Panels Expiration Dates

- Step 3: Assess Performance After Use

- Step 4: Ballistic Panels - Wear from Environmental Factors

- Step 5: Consult With a Ballistic Gear Professional

- Restore Your Confidence With Certified Ballistic Protection

- Frequently Asked Questions

- Recommended

Ballistic panels are the backbone of personal protection gear, relied on by thousands every day for life-saving defense. Most people assume that as long as there are no obvious holes or rips, their vest is doing its job. Surprise—experts warn that even minor surface changes can signal invisible damage that puts you at risk. The biggest danger might be trusting armor that looks fine but is secretly past its prime.

Table of Contents

- Step 1: Inspect For Visible Damage

- Step 2: Check Expiration Dates And Manufacturer Guidelines

- Step 3: Assess Performance After Use

- Step 4: Evaluate Wear From Environmental Factors

- Step 5: Consult With A Ballistic Gear Professional

Quick Summary

| Key Point | Explanation |

|---|---|

| 1. Inspect for visible damage regularly | Examine ballistic panels for punctures, tears, or discoloration to ensure their effectiveness and integrity. |

| 2. Check expiration dates diligently | Adhere to manufacturer guidelines, typically recommending replacement every 5 to 7 years for optimal protection. |

| 3. Assess performance post-use | Evaluate panels after significant use for unseen stress or damage, even if no visible signs are present. |

| 4. Evaluate environmental wear | Monitor storage and usage conditions that may affect material integrity and lead to potential degradation. |

| 5. Consult professionals for thorough evaluations | Seek expert assessments that utilize advanced techniques to detect material changes that may compromise safety. |

What is soft body armor made of?

Step 1: Inspect for Visible Damage on Ballistic Panels

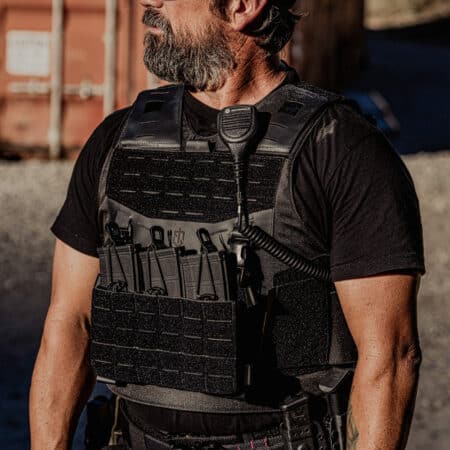

Begin by laying out your ballistic panel on a clean, flat surface with adequate lighting. Natural daylight or bright overhead lighting will help you identify even minor imperfections that might indicate structural compromise. Look carefully for any signs of physical damage such as punctures, tears, cuts, or significant abrasions. Pay special attention to the panel’s edges and corners, where wear and stress are most likely to manifest.

Carefully examine the panel’s surface texture and material integrity. Any visible deformation, bubbling, cracking, or unusual discoloration could signal internal structural breakdown. Run your hands gently across the panel’s surface, feeling for any irregularities or inconsistencies in the material that might not be immediately visible. Key indicators that warrant immediate replacement include:

- Visible punctures or holes larger than 1/8 inch in diameter

- Deep scratches that penetrate more than the surface layer

- Noticeable warping or structural deformation

- Evidence of chemical exposure or degradation

Even minor damage can dramatically reduce the panel’s ability to stop projectiles, potentially putting your life at risk.

| Step | Main Objective | Key Action |

|---|---|---|

| Inspect for visible damage | Identify signs of physical deterioration | Perform detailed visual and tactile inspection |

| Check expiration dates and guidelines | Verify service life and adherence to protocol | Locate and review manufacturer label |

| Assess performance after use | Detect performance loss from stress events | Examine flexibility, sound, weight |

| Evaluate environmental wear | Reveal degradation due to environmental exposure | Check for changes in texture, flexibility |

| Consult with a ballistic gear professional | Obtain expert analysis for conclusive results | Provide documentation, request professional inspection |

Step 2: Ballistic Panels Expiration Dates

Understanding the lifespan of your ballistic panels is crucial for maintaining optimal protection. Unlike typical protective gear, body armor has a finite service period that requires careful tracking and adherence to manufacturer specifications. Ballistic panels are not designed for indefinite use, and their protective capabilities can degrade over time due to environmental exposure, material stress, and cumulative wear.

Locate the manufacturer’s label, typically sewn into the interior of the panel or printed on a distinct tag. This label contains critical information including the manufacturing date, recommended replacement date, and specific care instructions. Most manufacturers establish a standard service life between 5 to 7 years from the production date, though this can vary based on the specific material composition and intended usage environment.

Pay close attention to the recommended replacement timeline provided by the manufacturer. According to the Justice Technology Information Center, each ballistic panel has unique degradation characteristics influenced by factors such as:

- Frequency of use

- Environmental exposure

- Storage conditions

- Physical stress and impact history

If you cannot locate the original manufacturer’s guidelines or the label has become illegible, contact the manufacturer directly. Many companies maintain detailed records and can provide specific guidance based on your panel’s serial number or production batch. Some manufacturers offer free inspections or consultations to help determine whether your panel remains within acceptable protective parameters.

Verification is straightforward: confirm the manufacturing date, calculate the recommended service period, and assess whether your current panel falls within the manufacturer’s approved usage timeline. When in doubt, always err on the side of caution and consider replacement. Your personal safety is worth far more than the cost of a new protective panel.

Step 3: Assess Performance After Use

Evaluating your ballistic panel’s performance after significant use or potential impact events is a critical step in maintaining your personal protection equipment. While ballistic panels are engineered to withstand substantial stress, every exposure can potentially compromise their structural integrity and protective capabilities.

Comprehensive post-use assessment requires a systematic approach that goes beyond simple visual inspection. Start by thoroughly examining the panel for any signs of stress or damage that might not be immediately apparent. Look for subtle indicators like compression marks, fiber distortion, or microscopic structural changes that could signify internal weakening. Pay special attention to areas that might have experienced direct impact or significant strain during your most recent use.

Research from the National Institute of Justice emphasizes the importance of understanding that ballistic panels undergo cumulative stress. Even if no visible damage is present, repeated exposure to environmental conditions, physical stress, or potential impact can gradually erode the panel’s protective capabilities. Consider your panel’s recent history carefully: Has it been subjected to extreme temperatures? Experienced significant physical compression? Been exposed to moisture or chemical environments?

Key performance assessment indicators include:

- Noticeable changes in panel flexibility or rigidity

- Unusual sounds when the panel is manipulated

- Unexplained weight variations

- Visible deformation or material warping

- Compromised protective layer separation

Document your assessment meticulously. Take detailed photographs documenting the panel’s condition from multiple angles. If possible, consult with the manufacturer or a professional armor technician who can provide a comprehensive evaluation. Some manufacturers offer professional inspection services that can definitively determine whether your panel remains within acceptable performance parameters.

Remember, your ballistic panel represents a critical line of defense. When in doubt about its performance or integrity, replacement is always the safest option. The marginal cost of a new panel is insignificant compared to the potential life-saving protection it provides.

Step 4: Ballistic Panels – Wear from Environmental Factors

Environmental exposure represents a significant yet often overlooked factor in ballistic panel degradation. Your protective equipment is continuously subjected to a range of conditions that can subtly compromise its structural integrity, making systematic environmental assessment crucial for maintaining optimal performance.

Comprehensive environmental wear evaluation requires a holistic approach that considers multiple potential degradation sources. Begin by examining how your ballistic panel has been stored and used. Temperature fluctuations, humidity levels, direct sunlight exposure, and chemical interactions can all contribute to material breakdown. Extreme temperatures are particularly damaging, with both intense heat and cold potentially causing molecular changes in the panel’s protective materials.

Key environmental wear indicators include:

- Discoloration or fading of panel material

- Chalky or powdery surface texture

- Visible material brittleness

- Loss of original flexibility

- Unexpected changes in panel weight

Pay special attention to storage conditions. Ballistic panels stored in damp environments are vulnerable to moisture-related degradation, which can promote mold growth, material oxidation, and structural weakening. Similarly, panels exposed to direct sunlight or stored in vehicles with extreme temperature variations face accelerated material stress.

Conduct a thorough tactile and visual inspection, feeling for changes in material consistency. Healthy ballistic panels should maintain uniform texture and flexibility. Any areas that feel unusually hard, brittle, or show uneven surface characteristics could indicate significant environmental damage. Compare the panel’s current condition to its original state, noting any subtle changes that might compromise its protective capabilities.

Documentation is critical. Maintain a detailed log tracking your panel’s environmental exposure, including storage locations, temperature ranges, and any significant environmental events. This record can help you and manufacturers understand potential degradation patterns and make informed replacement decisions. When environmental wear raises concerns about performance, professional inspection or replacement should be your priority.

Step 5: Consult With a Ballistic Gear Professional

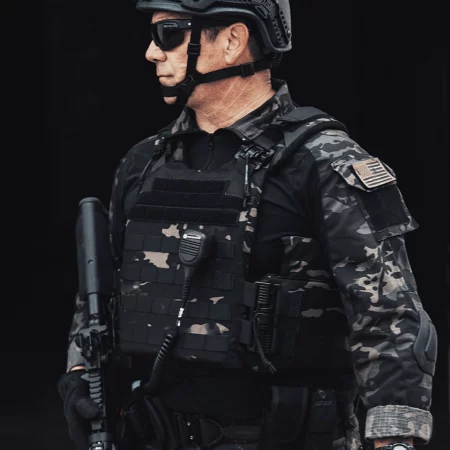

Navigating the complex world of ballistic protection requires expertise beyond personal assessment. Professional consultation represents the final and most critical step in determining whether your ballistic panels need replacement. Specialized technicians possess diagnostic capabilities that go far beyond visual inspection, utilizing advanced techniques to evaluate your protective equipment’s true performance potential.

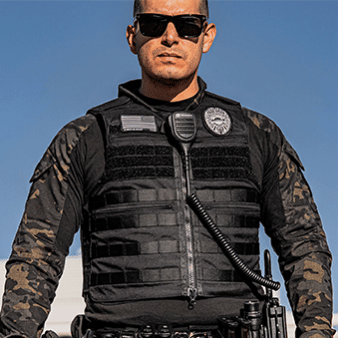

Seek out professionals who specialize in ballistic gear evaluation, preferably those with direct experience in law enforcement, military, or tactical equipment maintenance. When selecting a consultant, prioritize professionals with certifications from recognized ballistic standards organizations. Look for experts who can provide comprehensive panel assessments, including detailed analysis of material integrity, structural performance, and potential compromising factors.

According to the National Institute of Justice’s body armor guidelines, professional assessment involves sophisticated diagnostic processes that examine microscopic material changes invisible to the untrained eye. These experts utilize specialized equipment to detect subtle structural variations that could significantly impact protective capabilities.

Key consultation points to discuss with a ballistic gear professional include:

- Complete panel usage history

- Detailed environmental exposure records

- Any known impact or stress events

- Manufacturer specifications and recommended service life

- Potential material degradation indicators

When scheduling your consultation, prepare comprehensive documentation about your panel’s history. Detailed records enhance the professional’s ability to make accurate assessments. If you have specific concerns about protective gear configurations, discuss these during your consultation to ensure a thorough evaluation.

Remember that professional consultation is an investment in your personal safety. The minimal cost of an expert assessment far outweighs the potential risk of relying on compromised protective equipment. Trust the expertise of certified professionals who understand the nuanced science behind ballistic panel performance and can provide authoritative recommendations tailored to your specific gear and usage requirements.

How to clean soft body armor?

Soft armor is not machine washable. Water can damage and loosen aramid fibers, and deteriorate their ballistic protection capabilities. When cleaning your armor, remove the armor inserts from the carrier vest. Then you can wash the vest in a machine and hang it to dry. Make sure that the vest is completely dry before you enter the soft armor panels back into it, and don’t use fabric softeners. You may also need to clean your ballistic panels after some time.

Restore Your Confidence With Certified Ballistic Protection

Noticing signs of wear, damage, or expiration in your ballistic panels can leave you feeling vulnerable when safety matters most. This article makes it clear that even small imperfections or expired panels may reduce your protection against threats. If your inspection has revealed punctures, fading, brittleness, or if your gear has reached its recommended service life, your safety is not something to compromise.

Documenting your findings is crucial. Take clear, well-lit photographs of any damage you discover. The following checklist summarizes key indicators and actions for assessing whether your ballistic panel should be replaced. Use this table as a quick reference during inspections.

| Indicator | Description | Recommended Action |

|---|---|---|

| Punctures or holes | Holes greater than 1/8 inch or deep scratches | Replace panel immediately |

| Discoloration or fading | Noticeable changes in color or uneven fading | Inspect further, consider replacement |

| Warping or deformation | Panel loses original shape or structural form | Replace panel |

| Chemical exposure evidence | Signs of burns, stains, or chemical residue | Replace panel |

| Excessive brittleness | Panel feels unusually rigid or fragile | Replace panel |

| Weight or flexibility changes | Unexpected increase or loss in weight/flexibility | Inspect further, consider replacement |

| Impact event involvement | Panel subjected to direct impact | Replace panel regardless of visible damage |

Now is the time to take control. Upgrade your personal protection with AcelinkArmor’s wide selection of body armor solutions. Explore our ballistic helmets and discover comprehensive tactical gear that meets the latest industry standards. Every product includes transparent specifications and trusted compliance for your peace of mind. Visit AcelinkArmor.com today and equip yourself with dependable, high-quality protective gear. Don’t risk your well-being with outdated panels. Choose proven defense engineered for real-world threats—shop now and protect what matters most.

Frequently Asked Questions

What are the signs that my ballistic panel needs to be replaced?

Visible damage such as punctures, tears, or significant abrasions, as well as structural deformations like warping or bubbling, are key indicators. If you notice any of these issues, it is crucial to replace the panel immediately.

How often should I check my ballistic panels for expiration?

You should check your ballistic panels for expiration at least once a year. Most manufacturers recommend a replacement timeline of 5 to 7 years from the production date, so keep track of the manufacturing date and follow any specific guidelines provided by the manufacturer.

What should I do if my ballistic panel has been involved in an impact event?

If your ballistic panel has experienced any direct impact, it should be considered for replacement, even if no visible damage is present. The internal microstructure can sustain damage that is not immediately apparent but can compromise protective capabilities.

How can environmental factors affect the lifespan of my ballistic panels?

Environmental factors such as extreme temperatures, humidity, and exposure to sunlight or chemicals can degrade the materials in ballistic panels. Regularly assess for signs of discoloration, brittleness, or any changes in texture that might indicate environmental wear.

Recommended

- 8×10″ Bulletproof and Stabproof Panel – Ace Link Armor

- Stab-Proof and Bulletproof Armor Panel 6×13″ – Ace Link Armor

- Concealed Armor T-shirt Soft Armor Panel – Ace Link Armor

- Bulletproof Armor Insert 10×12″ Aramid Flexcore – Ace Link Armor

- Understanding Paint Protection Film Lifespan: Insights for Professionals 2025 – AEONCUT PPF Pre-cut Cutting software