- Table of Contents

- Quick Summary

- Step 1: Identify Your Protection Needs

- Step 2: Research Helmet Types and Standards

- Step 3: Evaluate Ballistic Helmets Based on Fit and Comfort

- Step 4: Compare Features and Functionality

- Step 5: Test Ballistic Helmet for Quality

- Step 6: Make Your Purchase Decision

- Experience Trusted Ballistic Helmet Solutions From Ace Link Armor

- Frequently Asked Questions

- Recommended

Choosing a ballistic helmet is not just about grabbing any hard shell and hoping for the best. Helmets can differ wildly in protection levels, materials, and fit—some rated for speeding rifle rounds, while others only deflect pistol fire. Most people think comfort and features come second, but poor fit or cheap construction can make even the most expensive helmet dangerous when it counts. Knowing which factors truly matter will change how you protect yourself.

Table of Contents

- Step 1: Identify Your Protection Needs

- Step 2: Research Helmet Types And Standards

- Step 3: Evaluate Helmets Based On Fit And Comfort

- Step 4: Compare Features And Functionality

- Step 5: Test For Quality And Durability

- Step 6: Make Your Purchase Decision

Quick Summary

| Key Point | Explanation |

|---|---|

| 1. Identify Protection Needs | Assess your unique protection needs based on your role, threats, and environment to ensure optimal helmet selection. |

| 2. Research Helmet Types and Standards | Understand different helmet materials and NIJ standards to make informed decisions about protective capabilities. |

| 3. Evaluate Fit and Comfort | Select a helmet that fits snugly and comfortably to maintain safety and operational effectiveness during extended wear. |

| 4. Compare Features and Functionality | Analyze helmet features like weight, mountability, and environmental adaptability to ensure compatibility with your needs. |

| 5. Test for Quality and Durability | Conduct thorough inspections and practical tests to confirm your helmet’s structural integrity and reliability in various conditions. |

Step 1: Identify Your Protection Needs

Selecting the right ballistic helmet begins with a critical self-assessment of your specific protection requirements. Understanding your unique needs is the foundation of choosing gear that offers optimal safety and performance. Protection needs vary dramatically depending on your professional role, anticipated threat levels, and operational environment.

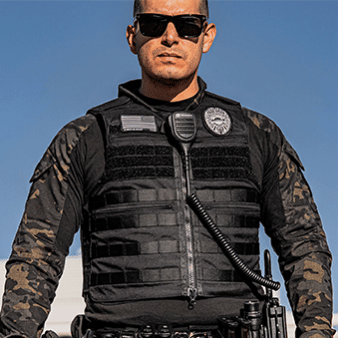

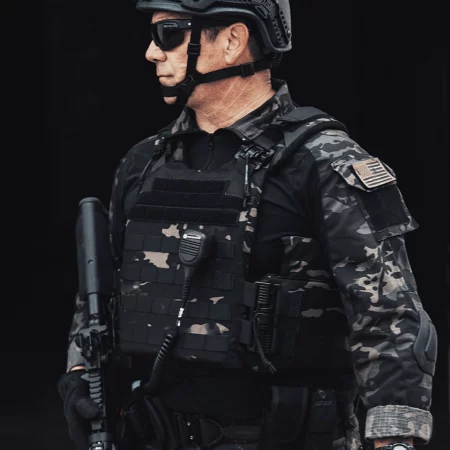

Law enforcement officers, military personnel, security professionals, and civilian shooters each face distinct risk scenarios that demand tailored helmet solutions. A patrol officer working in an urban environment will have different protection priorities compared to a special operations soldier deployed in a high-conflict zone. Your helmet selection must align precisely with the potential ballistic threats you might encounter.

To effectively identify your protection needs, consider several key factors. Threat assessment is paramount – evaluate the specific types of projectiles and weapons prevalent in your operational context. Urban environments might present different ballistic risks compared to rural or combat zones. Analyze historical incident data, local crime statistics, and potential threat scenarios relevant to your professional or personal security requirements.

Physical requirements also play a crucial role in helmet selection. Body type, head circumference, and potential helmet weight are critical considerations. A helmet providing maximum protection might be counterproductive if it’s too heavy or uncomfortable, potentially limiting mobility and situational awareness. Professionals who require extended wear periods must balance protection levels with ergonomic comfort.

According to the National Institute of Justice, protection needs can be systematically evaluated through comprehensive threat modeling. Key verification criteria include:

- Understanding expected projectile types and velocities

- Assessing potential engagement distances

- Evaluating personal mobility requirements

- Determining acceptable weight and comfort thresholds

By methodically analyzing these factors, you’ll develop a clear framework for identifying the precise ballistic helmet protection level that matches your specific needs, ensuring both safety and operational effectiveness.

Step 2: Research Helmet Types and Standards

Researching ballistic helmet types and standards represents a crucial phase in selecting the right protective gear. Not all helmets offer identical protection, and understanding the nuanced differences can mean the difference between adequate safety and potential vulnerability. Your research should encompass a comprehensive evaluation of helmet classifications, materials, protection levels, and industry standards.

Ballistic helmets are typically categorized into several standard types based on their protective capabilities. Shell materials play a critical role in determining helmet performance, with modern options including aramid fibers, ultra-high-molecular-weight polyethylene (UHMWPE), and advanced composite materials. Each material offers distinct advantages in terms of weight, durability, and ballistic resistance. Some professionals prefer lightweight UHMWPE helmets for extended wear, while others prioritize maximum protection through multi-layered composite designs.

Standards established by organizations like the National Institute of Justice (NIJ) provide a critical framework for evaluating helmet performance. According to the National Institute of Justice, helmet standards classify protective capabilities through rigorous testing protocols that measure resistance against specific projectile types and velocities. Protection levels range from handgun threats to high-velocity rifle rounds, with each level representing increasingly sophisticated defensive capabilities.

When conducting your research, pay close attention to specific performance metrics. Evaluate helmets not just on their protective ratings, but also on critical secondary factors like weight distribution, comfort, compatibility with communication systems, and mounting options. Read more about the different types of ballistic helmets to gain deeper insights into these nuanced selection criteria.

Your verification checklist for completing this research phase should include:

- Documenting NIJ protection level ratings for potential helmet selections

- Comparing shell materials and their specific performance characteristics

- Understanding threat scenarios relevant to your professional environment

- Assessing ergonomic features beyond pure ballistic protection

By methodically exploring these dimensions, you’ll develop a comprehensive understanding of ballistic helmet types and standards, positioning yourself to make an informed protective gear selection.

Here is a summary comparison table of typical ballistic helmet shell materials by weight, durability, and ballistic resistance, to help you quickly understand the trade-offs when researching helmet types and standards.

| Shell Material | Relative Weight | Durability | Ballistic Resistance Level |

|---|---|---|---|

| Aramid Fibers (e.g., Kevlar) | Moderate | High | Strong against pistol & some rifle rounds |

| UHMWPE (Ultra-high-molecular-weight Polyethylene) | Lightest | Very High | Effective, especially against pistols |

| Advanced Composites | Moderate to Heavy | Very High | Optimized for both pistol & rifle threats |

Step 3: Evaluate Ballistic Helmets Based on Fit and Comfort

Fit and comfort are absolutely critical when selecting a ballistic helmet, as these factors directly impact your safety, performance, and endurance during extended wear. A poorly fitting helmet can compromise protection and create significant operational challenges. Your goal is to find a helmet that feels like a natural extension of your protective gear, offering maximum security without restricting movement or causing physical discomfort.

Precise measurement is the foundation of finding the right helmet. Head circumference determines your baseline sizing, so you’ll want to measure approximately one inch above your eyebrows using a flexible measuring tape. Professional users should consider additional factors beyond basic measurements, such as head shape, potential gear compatibility, and individual anatomical variations. According to research from the U.S. Army Safety Center, a well-fitted helmet should feel snug without creating pressure points or causing unnecessary strain.

When evaluating helmet comfort, pay close attention to weight distribution, padding quality, and adjustability mechanisms. Modern ballistic helmets incorporate advanced ergonomic designs that minimize neck fatigue and provide superior impact absorption. Look for helmets with adjustable suspension systems that allow fine-tuning of fit, strategic padding placement, and moisture-wicking materials that enhance comfort during prolonged use. The chinstrap is another critical component – it should secure the helmet firmly without causing chafing or restricting blood circulation.

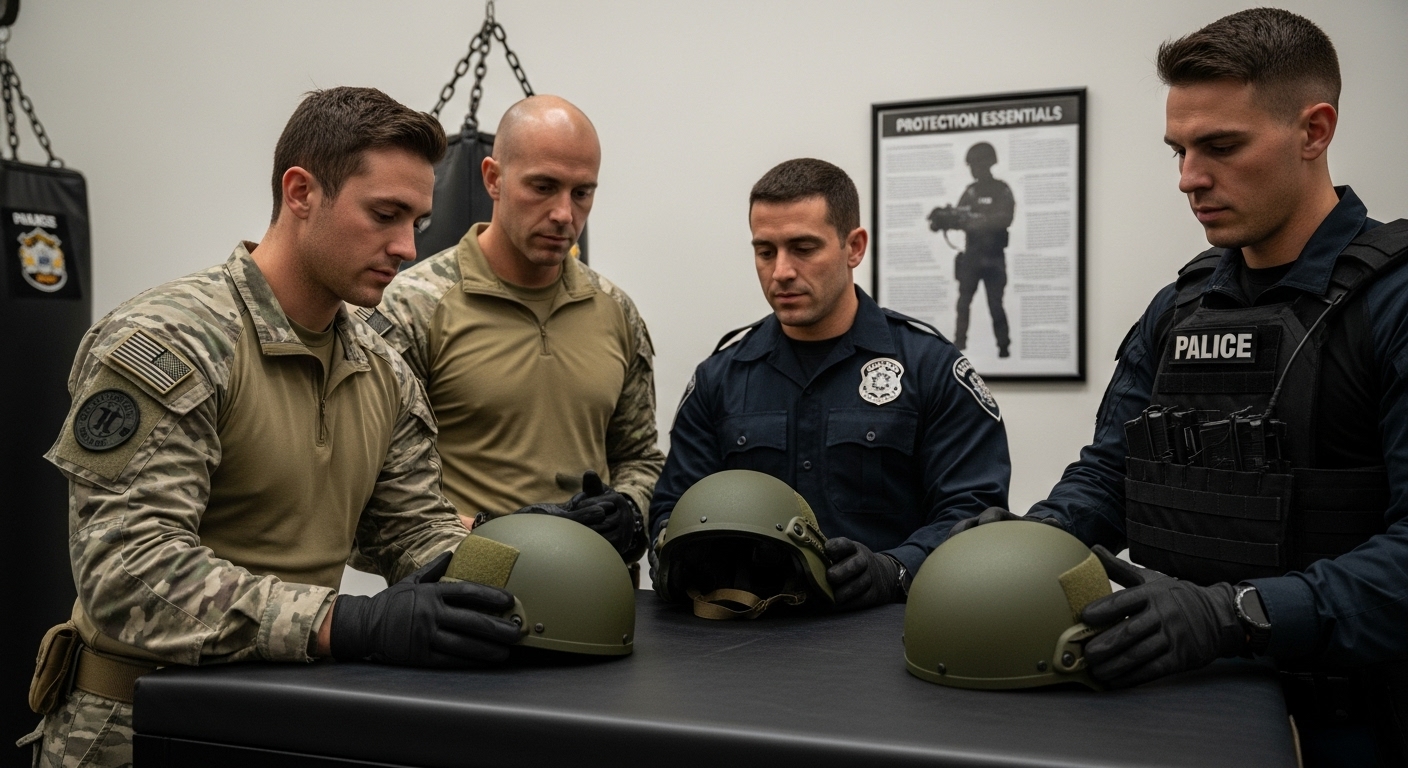

Practical testing is essential in determining true comfort and fit. Learn more about selecting the perfect ballistic helmet to understand the nuanced considerations. Whenever possible, physically try on multiple helmets while wearing your typical operational gear. Simulate realistic movement patterns, test communication equipment compatibility, and assess how the helmet integrates with other protective equipment like body armor or night vision systems.

Your verification checklist for fit and comfort includes:

- Helmet sits level and covers critical skull areas

- No more than 1-2 finger widths of movement when shaking head

- Minimal pressure points during 30-minute wear test

- Comfortable with full gear ensemble

- Chinstrap allows proper adjustment without restriction

Remember that comfort isn’t a luxury – it’s a critical performance factor that directly impacts your operational effectiveness and personal safety.

Below is a checklist table summarizing key verification steps to evaluate the fit and comfort of a ballistic helmet, ensuring you choose protective gear that offers security and seamless integration with your operational needs.

| Fit & Comfort Checklist | Verification Criteria Description |

|---|---|

| Helmet Sits Level | Ensures helmet covers all critical skull areas without tilting or shifting during movement. |

| Limited Movement | No more than 1-2 finger widths of movement when shaking your head in any direction. |

| No Pressure Points | Helmet stays comfortable, even during a 30-minute wear test, with no sore spots or strain. |

| Comfortable With Full Gear Ensemble | Remains comfortable when worn with all your typical operational equipment and accessories. |

| Adjustable Chinstrap Fit | Chinstrap secures the helmet snugly without causing discomfort or restrictiveness. |

Step 4: Compare Features and Functionality

Comparing ballistic helmet features and functionality goes far beyond simple protective ratings. Your helmet is a complex piece of tactical equipment that must integrate seamlessly with your operational requirements, communication systems, and additional gear. This step demands a comprehensive evaluation of each helmet’s unique capabilities and potential limitations.

Material composition and weight distribution represent critical factors in functionality. Modern ballistic helmets leverage advanced materials like ultra-high-molecular-weight polyethylene (UHMWPE), offering superior protection while minimizing weight burden. According to research on combat helmet development, technological advancements have dramatically improved helmet performance, providing enhanced protection without sacrificing mobility.

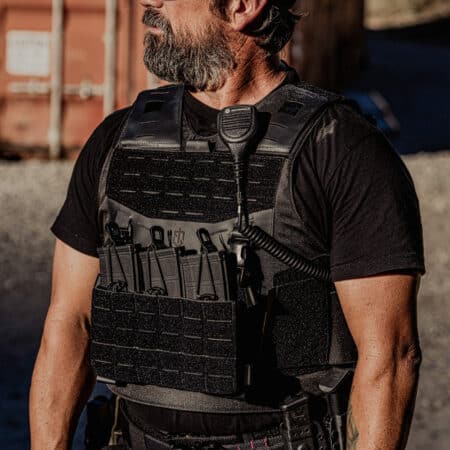

Mounting capabilities emerge as another crucial consideration. Professional users need helmets that support seamless integration with night vision equipment, communication systems, and mission-specific accessories. Look for helmets with standardized rail systems and adaptable mounting points that allow quick configuration changes. Evaluate the helmet’s compatibility with your existing gear, ensuring smooth attachment mechanisms for critical equipment like communications headsets, cameras, or tactical lighting systems.

Explore advanced helmet configurations to understand the nuanced world of tactical helmet engineering. Beyond basic protection, consider additional functional features such as ventilation systems, moisture-wicking internal liners, and quick-release mechanisms. These seemingly minor details can significantly impact performance during extended operational periods.

Environmental adaptability represents another key functionality metric. Different operational contexts demand specialized helmet features. Urban law enforcement professionals might prioritize lightweight, low-profile designs, while military personnel might require more robust, modular systems that support extreme environmental conditions.

Your verification checklist for comparing helmet features includes:

- Confirmed compatibility with existing mission-critical equipment

- Comprehensive assessment of mounting capabilities

- Evaluation of material durability and weight characteristics

- Verification of environmental performance range

- Assessment of additional integrated features

Remember that functionality is about creating a holistic system that enhances your operational effectiveness while providing maximum protection.

Step 5: Test Ballistic Helmet for Quality

Testing a ballistic helmet’s quality and durability is the final critical step in ensuring your investment provides genuine protection. Quality assessment goes far beyond surface-level inspections, requiring a methodical approach that evaluates structural integrity, material performance, and long-term reliability under various stress conditions.

Visual and tactile inspection serves as your initial quality assessment. Examine the helmet meticulously for any manufacturing inconsistencies, such as uneven shell thickness, potential delamination, or structural imperfections. Pay close attention to seam quality, padding integrity, and mounting hardware connections. Small defects can compromise the helmet’s overall protective capabilities, potentially creating life-threatening vulnerabilities during critical moments.

According to research from the National Institute of Justice, professional-grade ballistic helmets must meet rigorous standardized testing protocols. These standards evaluate impact resistance, penetration protection, and structural stability under simulated threat conditions. While comprehensive ballistic testing typically requires specialized facilities, you can perform several practical durability assessments.

Learn more about advanced helmet testing techniques to understand the nuanced evaluation process. Simulate real-world stress scenarios by conducting thorough functional tests. Assess the helmet’s performance during movement, checking for stability, weight distribution, and potential shifting during dynamic activities. Evaluate how the helmet interfaces with other critical gear like communication systems, night vision equipment, and protective eyewear.

Environmental resilience represents another crucial durability metric. Test the helmet’s response to temperature variations, humidity, and potential chemical exposures. Examine the helmet’s protective coatings and material integrity after exposure to different environmental conditions. A high-quality ballistic helmet should maintain its structural and protective properties across diverse operational environments.

Your comprehensive verification checklist for quality and durability includes:

- No visible manufacturing defects or structural inconsistencies

- Stable performance during dynamic movement tests

- Proper interface with additional tactical equipment

- Resistance to environmental stress factors

- Maintenance of protective capabilities under varied conditions

Remember that durability testing is not just about identifying potential weaknesses – it’s about confirming your helmet’s reliability when you need protection most.

Step 6: Make Your Purchase Decision

Making the final purchase decision for your ballistic helmet represents the culmination of a meticulous selection process. This is not merely a transaction, but a critical investment in your personal safety. Your comprehensive research, testing, and evaluation now converge into a decisive moment that requires careful consideration of multiple factors beyond simple price point.

Financial considerations are important, but they should never compromise your protection. Ballistic helmets are life-saving equipment, not commodity products. Evaluate the total value proposition, considering long-term durability, manufacturer reputation, warranty coverage, and potential replacement costs. Professional-grade helmets represent an investment in your safety, with pricing typically reflecting advanced material technologies, rigorous testing, and precise manufacturing standards. According to research from the National Institute of Justice, meeting established protective standards requires significant research and development investment.

Prioritize purchasing from reputable manufacturers with proven track records in ballistic protection equipment. Look for manufacturers that provide comprehensive documentation, including NIJ certification, detailed performance specifications, and transparent testing results. Verify the manufacturer’s commitment to quality by examining their customer support infrastructure, replacement policies, and professional endorsements from law enforcement or military organizations.

Explore our comprehensive helmet selection to inform your final decision, considering the nuanced factors that matter most. Consider additional factors such as the manufacturer’s research and development history, their responsiveness to technological advancements, and their ability to provide ongoing support for their products.

Evaluate your potential purchase against your specific operational requirements. A helmet that excels in one professional context might be suboptimal in another. Your selection should reflect a precise alignment between the helmet’s capabilities and your unique performance needs.

Use this comprehensive purchase decision checklist to make sure your final ballistic helmet selection offers verified protection, professional quality, and value for long-term safety and operational confidence.

| Purchase Decision Checklist | What to Verify |

|---|---|

| Alignment with Protection Needs | Helmet matches your professional requirements and anticipated threat scenarios |

| Verified Manufacturer Reputation | Manufacturer has proven track record, positive endorsements, and transparent specifications |

| NIJ or Equivalent Certification | Product meets recognized ballistic testing and certification standards |

| Warranty and Support Coverage | Clear warranty policy and ongoing customer support offered by manufacturer |

| Value Within Budget | Helmet justifies its cost with durable construction, features, and long-term performance |

Your final verification checklist for the purchase decision includes:

- Confirmed alignment with professional protection requirements

- Verified manufacturer credentials and reputation

- Comprehensive understanding of warranty and support options

- Budget assessment considering long-term value

- Confirmation of NIJ or equivalent certification standards

Remember that your ballistic helmet is more than equipment – it’s a critical layer of personal protection that could determine your safety in high-risk scenarios.

Experience Trusted Ballistic Helmet Solutions From Ace Link Armor

If you have spent time researching, measuring, and comparing ballistic helmets, then you know how overwhelming it can be to find real protection that actually fits your needs. It is not just about materials or standards. The true challenge is to balance comfort, verified protection, and seamless tactical compatibility—especially when your safety is on the line. This is exactly where most buyers struggle. You may worry about buying a helmet that falls short in fit or fails critical testing, leaving you at risk in the most important situations.

Take the last step with confidence. Explore AcelinkArmor.com’s ballistic helmets and see how our police and military-grade gear meets the strictest standards for professional and civilian users. Every helmet in our ballistic protection collection comes with verified NIJ-level testing and is built for real-world durability, ergonomic fit, and easy gear integration. Discover detailed product specs, trusted certifications, and real reviews—then secure your perfect helmet today for the confidence and safety you deserve. Visit AcelinkArmor.com and upgrade your protection before your next operation or range day.

Frequently Asked Questions

What factors should I consider when selecting a ballistic helmet?

When selecting a ballistic helmet, consider your specific protection needs, such as the types of threats you may encounter, the environment you operate in, and your physical requirements like head size and comfort preferences.

How important is the fit and comfort of a ballistic helmet?

Fit and comfort are critical for a ballistic helmet as a poor fit can compromise protection and hinder mobility. A well-fitted helmet should feel snug without pressure points and allow for prolonged wear without discomfort.

What materials are commonly used in ballistic helmets, and how do they affect performance?

Ballistic helmets are typically made from materials like aramid fibers, ultra-high-molecular-weight polyethylene (UHMWPE), and composite materials. Each material has different advantages regarding weight, durability, and ballistic resistance, which can affect the helmet’s overall performance.

How do I assess the quality and durability of a ballistic helmet?

To assess the quality and durability, conduct a visual inspection for manufacturing defects, check for compliance with national standards like those from the National Institute of Justice, and test the helmet’s performance during movement to ensure stability and comfort under operational conditions.

Recommended

- Types of Ballistic Helmets & How to Choose One

- What Should A Ballistic Helmet Protect From?

- Level IIIA Armor

- Swimmer’s Cut vs Standard Cut