- Table of Contents

- Quick Summary

- What is Passive Cooling Technology in Body Armor?

- The Importance of Temperature Control in Body Armor

- How Passive Cooling Technology Enhances Comfort and Safety

- Key Materials and Mechanisms in Passive Cooling Body Armor

- Real-World Applications and Future of Cooling in Body Armor

- Experience The Next Generation of Body Armor Comfort and Performance

- Frequently Asked Questions

- Recommended

Body armor keeps professionals safe, but it often turns into a personal sauna after just a few minutes in the field. Surprising as it sounds, the real innovation is not high-tech cooling packs or battery-powered gadgets. The secret is passive cooling technology, where advanced fabrics and smart materials can drop core body temperature dangerously less often—strategic thermal management can actually reduce heat strain and cut the risk of heat exhaustion. This flips the script on what most people expect from armor and reveals how staying cool might matter as much as stopping bullets.

The following table compares traditional body armor with passive cooling body armor, highlighting how key features differ and the impact on user experience.

| Feature | Traditional Body Armor | Passive Cooling Body Armor |

|---|---|---|

| Thermal Comfort | Traps heat, often uncomfortable | Regulates temperature, cooler to wear |

| Moisture Management | Limited, sweat accumulates | Advanced wicking, keeps skin drier |

| Need for External Power | Not applicable | Not required (uses material properties) |

| Physiological Impact | Higher risk of heat strain | Reduced heat strain, improved efficiency |

| Material Innovations | Standard fabrics and fibers | PCMs, 37.5 Technology, nanofibers |

| Long-Term Health Risks | Increased with heat accumulation | Lower due to better thermal management |

Table of Contents

- What Is Passive Cooling Technology In Body Armor?

- The Importance Of Temperature Control In Body Armor

- How Passive Cooling Technology Enhances Comfort And Safety

- Key Materials And Mechanisms In Passive Cooling Body Armor

- Real-World Applications And Future Of Cooling In Body Armor

Quick Summary

| Takeaway | Explanation |

|---|---|

| Passive cooling enhances thermal comfort | Advanced materials regulate body temperature without power, improving comfort and safety for wearers. |

| Moisture-wicking fabrics are critical | Fabrics that quickly move sweat away from skin help maintain optimal body temperature during wear. |

| Increased focus and performance under stress | Proper thermal management reduces cognitive fatigue, helping users maintain performance in high-pressure situations. |

| Long-term heat exposure poses health risks | Continuous high temperatures can lead to serious health issues and degrade body armor materials over time. |

| Future innovations aim at smart materials | Research indicates potential for dynamic materials that adjust thermal properties in real-time, enhancing comfort and performance further. |

What is Passive Cooling Technology in Body Armor?

Passive cooling technology represents an innovative approach to managing thermal comfort for individuals wearing body armor, addressing one of the most challenging aspects of personal protective equipment. Unlike active cooling systems that require external power sources, passive cooling technologies leverage advanced materials and design principles to naturally regulate body temperature and reduce heat stress.

The Science Behind Thermal Regulation in Body Armor

At its core, passive cooling technology works by manipulating how the body manages heat transfer and moisture. Researchers at MIT have demonstrated that strategic material design can significantly reduce thermal load without requiring electrical intervention. The primary mechanisms include:

- Moisture wicking fabrics that rapidly move sweat away from the skin

- Specialized fiber technologies that actively manage body heat

- Strategically designed layers that enhance air circulation and heat dissipation

These technologies are critical because body armor traditionally traps heat, creating uncomfortable and potentially dangerous conditions for wearers in high-stress environments. By incorporating advanced materials like 37.5 Technology and Phase Change Materials (PCMs), manufacturers can create garments that dynamically respond to the wearer’s body temperature.

At the core of every Thermacore™ base layer is a proprietary blend of performance fibers and active infrared particles that regulate your microclimate in real time.37.5® Fiber Technology responds to body-generated infrared heat by accelerating the removal of moisture vapor — before sweat forms — helping you stay drier, cooler, and more focused.The result: faster cool-down, less sweat accumulation, and enhanced comfort in the most demanding conditions.

Performance and Physiological Benefits of Wearing Body Armor

The implementation of passive cooling technologies offers substantial performance improvements. A comprehensive study published in PubMed revealed that strategic thermal management can reduce heat strain by promoting better airflow and moisture management under body armor. This translates to tangible benefits for professionals who rely on protective gear, including:

- Reduced risk of heat exhaustion

- Enhanced cognitive performance under thermal stress

- Increased comfort during prolonged wear

- Improved overall physiological efficiency

For those interested in learning more about thermal management strategies, our guide on body armor heat management provides comprehensive insights into the latest technological advancements in personal protective equipment.

The Importance of Temperature Control in Body Armor

Temperature control represents a critical yet often overlooked factor in body armor performance and user safety. Professionals operating in high-stress environments face significant physiological challenges when wearing protective gear that can rapidly elevate body heat and compromise operational effectiveness.

Physiological Stress and Performance Degradation

Research from the National Institute of Standards and Technology highlights the profound impact of thermal stress on human performance. When body temperature rises beyond optimal ranges, several critical physiological changes occur:

- Decreased cognitive processing speed

- Reduced decision-making capabilities

- Increased risk of heat-related medical complications

- Accelerated physical fatigue

Thermacore’s Fresh-2-Skin® technology embeds microencapsulated menthol directly into the fabric, releasing a cool-to-the-touch sensation as body heat rises. This instant, long-lasting effect helps reduce skin temperature perception and enhances comfort.

More than just freshness, the menthol infusion delays heat stress and supports focus during prolonged wear under armor. Ideal for high-heat missions or intense training, it creates a cooling microclimate from the moment it’s worn.

Long-Term Health and Equipment Integrity

Beyond immediate performance implications, prolonged exposure to excessive heat while wearing body armor can lead to significant long-term health risks. A comprehensive study revealed that increased body armor coverage correlates with higher core temperature elevation, potentially creating dangerous physiological strain.

Additionally, temperature fluctuations can impact the structural integrity of protective materials. High heat and humidity environments can gradually degrade the molecular structure of protective fibers, potentially compromising the armor’s ballistic resistance over time.

For those seeking deeper insights into thermal management strategies, our comprehensive guide on thermal comfort provides advanced techniques for maintaining optimal performance and protection.

How Passive Cooling Technology Enhances Comfort and Safety

Passive cooling technology in body armor represents a sophisticated approach to managing human thermal dynamics, transforming how professionals experience protection and performance in challenging environments. By integrating advanced materials and design principles, these technologies provide a comprehensive solution to thermal stress management without relying on external power sources.

Innovative Thermal Management Strategies

Research from the American Journal of Industrial Medicine demonstrates that strategic thermal management can significantly improve user comfort and operational efficiency. The key mechanisms of passive cooling technologies include:

- Directional moisture wicking that rapidly transfers sweat away from the skin

- Microclimate air circulation design that reduces heat accumulation

- Advanced fabric technologies that dynamically respond to body temperature

Thermal regulation is not just about comfort, but about maintaining peak physiological performance. By preventing excessive heat buildup, these technologies help users maintain cognitive sharpness, reduce fatigue, and minimize the risk of heat-related medical complications.

Performance and Protection Synergy in Body Armor

Passive cooling technologies achieve a delicate balance between maintaining ballistic protection and ensuring user comfort. Unlike traditional body armor that can create uncomfortable thermal environments, modern designs incorporate intelligent material science principles.

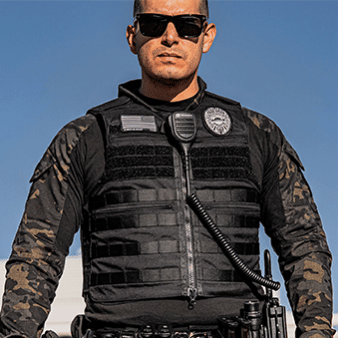

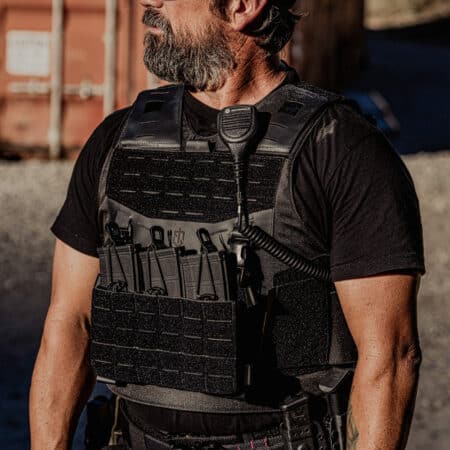

Specialized fabrics like Phase Change Materials (PCMs) and 37.5 Technology can absorb, store, and release heat precisely when needed. These materials function like a thermal reservoir, keeping the wearer’s body temperature within an optimal range. This approach is particularly crucial for professionals in high-stress environments such as law enforcement, military, and security sectors.

Our comprehensive body armor buying guide offers additional insights into selecting gear that prioritizes both protection and comfort, helping professionals make informed decisions about their personal safety equipment.

Key Materials and Mechanisms in Passive Cooling Body Armor

Passive cooling body armor technologies represent a sophisticated intersection of materials science, thermal engineering, and human physiology. By integrating advanced materials with intelligent design principles, manufacturers are revolutionizing how protective equipment manages heat and moisture in high-stress environments.

This table summarizes the advanced materials and mechanisms used in modern passive cooling body armor, along with their primary roles in enhancing performance.

| Key Material/Mechanism | Role in Passive Cooling |

|---|---|

| Phase Change Materials (PCMs) | Absorb, store, and release heat as needed |

| 37.5 Technology | Responds dynamically to humidity and temperature |

| Nanofiber Composites | Improve heat dissipation and moisture movement |

| Hydrogel/Aerogel Layers | Provide superior temperature regulation |

| UHMWPE with Thermal Properties | Enhances heat dissipation while providing strength |

| Ventilation Channels | Facilitate air flow to reduce heat buildup |

| Moisture Wicking Fabrics | Quickly move sweat away from the skin |

Advanced Material Technologies

Research from the National Institute of Standards and Technology highlights the critical role of material selection in thermal management. The most effective passive cooling technologies employ specialized materials engineered to manipulate thermal dynamics:

- Ultra-high molecular weight polyethylene (UHMWPE) with enhanced thermal dissipation properties

- Nanofiber composites that improve heat radiation and moisture management

- Hydrogel and aerogel layering systems for superior temperature regulation

Material performance goes beyond simple temperature reduction. These advanced technologies create a dynamic microclimate that actively responds to the wearer’s physiological changes, maintaining an optimal thermal balance without compromising ballistic protection.

![]()

Thermal Management Mechanisms

The core principle of passive cooling body armor involves creating intelligent thermal pathways that naturally manage heat transfer. Innovative mechanisms include directional moisture wicking, strategic ventilation channels, and phase-change materials that absorb and release heat precisely when needed.

Specialized fabrics like 37.5 Technology and Phase Change Materials (PCMs) can transform how body armor interacts with human thermal regulation. These materials function as sophisticated thermal reservoirs, actively managing heat accumulation and dissipation without external energy inputs.

Our Cataphract ULTRA Bulletproof Vest represents a prime example of how cutting-edge material technologies can be integrated into body armor design, providing professionals with enhanced comfort and protection.

Real-World Applications and Future of Cooling in Body Armor

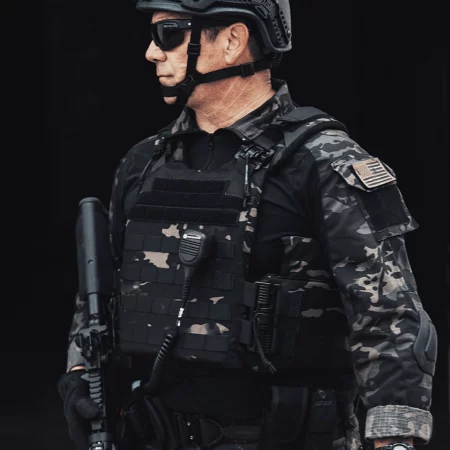

Passive cooling technologies are rapidly transforming body armor from mere protective equipment into sophisticated thermal management systems that enhance human performance across diverse operational environments. As professionals face increasingly complex and challenging scenarios, the integration of advanced cooling mechanisms becomes not just a comfort feature, but a critical operational advantage.

Professional Sector Implementations

Research from the Journal of Military Medicine demonstrates the profound impact of thermal regulation technologies across multiple professional sectors. Critical applications include:

- Law enforcement personnel operating in urban heat zones

- Military units deployed in extreme climate conditions

- Emergency response teams managing high-intensity rescue operations

- Security professionals working extended shifts in challenging environments

Thermal performance directly correlates with operational effectiveness. By maintaining optimal body temperature, professionals can sustain cognitive clarity, physical endurance, and rapid decision-making capabilities even under extreme stress and environmental challenges.

Emerging Technologies and Future Trajectories

The future of body armor cooling technologies points toward increasingly intelligent and adaptive systems. Emerging research suggests the development of smart materials that can dynamically adjust thermal properties in real-time, potentially incorporating nanotechnology and biomimetic design principles.

Innovative approaches like graphene-based cooling systems and responsive phase-change materials are pushing the boundaries of what’s possible in thermal management. These technologies aim to create body armor that not only protects against physical threats but actively supports the wearer’s physiological performance.

Our exploration of soft graphene armor technologies provides insight into how cutting-edge materials are revolutionizing personal protective equipment, promising lighter, more responsive, and more comfortable solutions for professionals who demand the highest performance standards.

Experience The Next Generation of Body Armor Comfort and Performance

Are you struggling with heat buildup and discomfort every time you put on your body armor? The article highlights how traditional armor can trap heat and cause dangerous physiological stress, lowering your focus and energy in critical moments. With passive cooling technology now transforming the industry, you deserve equipment that works with your body, not against it. Discover the difference with armor designed to manage heat, moisture, and comfort using innovations like Phase Change Materials and advanced layering.

Choose protection that lets you perform at your best without the threat of heat exhaustion. Explore our curated selection of modern body armor with cutting-edge cooling features, including the Cataphract ULTRA Bulletproof Vest. See how updated designs on AcelinkArmor.com deliver real physiological advantages. Make your move now to stay safer, cooler, and more capable during every mission.

Frequently Asked Questions

What is passive cooling technology in body armor?

Passive cooling technology refers to innovative materials and design principles that naturally regulate body temperature without requiring external power. It enhances comfort and reduces heat stress for individuals wearing body armor.

How does passive cooling technology improve performance for body armor users?

It improves performance by promoting better airflow, moisture management, and reducing heat strain, which leads to enhanced cognitive performance, decreased risk of heat exhaustion, and increased comfort during prolonged wear.

What materials are commonly used in passive cooling body armor?

Common materials include advanced fabrics like Phase Change Materials (PCMs) and 37.5 Technology, ultra-high molecular weight polyethylene (UHMWPE), and nanofiber composites that enhance thermal dissipation and moisture management.

Why is temperature control important in body armor?

Temperature control is crucial because excessive heat can lead to decreased cognitive function, decision-making capabilities, and increased risk of heat-related complications, directly impacting user safety and performance in high-stress environments.

Recommended

- Understanding Thermal Comfort While Wearing Body Armor – Ace Link Armor

- Body armor heat management – Why Heat Is the Hidden Enemy – Ace Link Armor

- The Science Behind Graphene Enhanced Armor – Ace Link Armor

- How to care for Body Armor – Ace Link Armor